Alloy Steel vs Carbon Steel – What Does Roto-Disc Use?

Material choice is pivotal in determining product durability, performance, and reliability for industrial engineers and manufacturers. Alloy and carbon steel are commonly used materials, but

Material choice is pivotal in determining product durability, performance, and reliability for industrial engineers and manufacturers. Alloy and carbon steel are commonly used materials, but

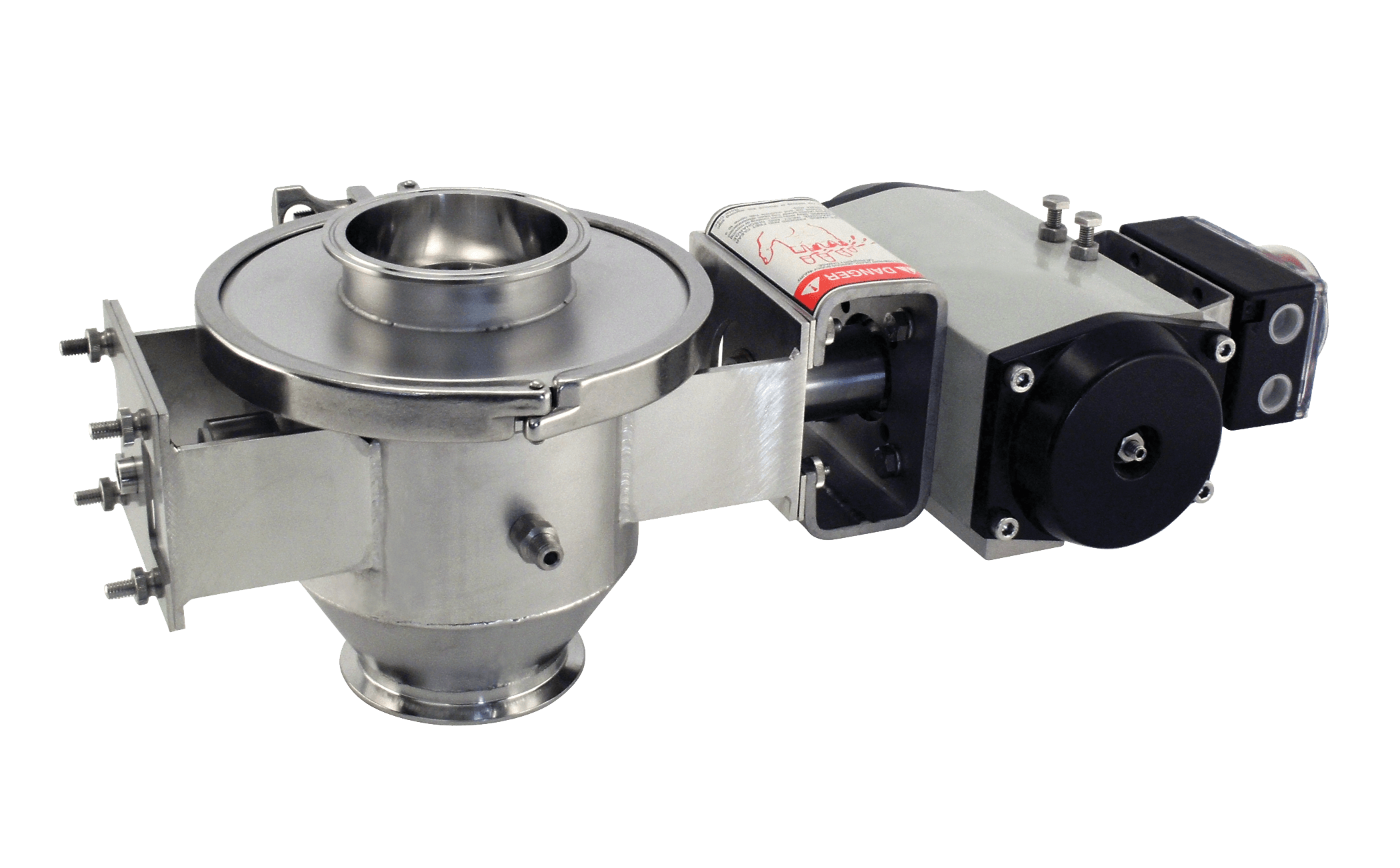

Roto-Disc® Inc’s inflatable seal mechanical interlock system for the Roto-Flate® valve enhances its reliability and causes it to fail closed and inflated in the case

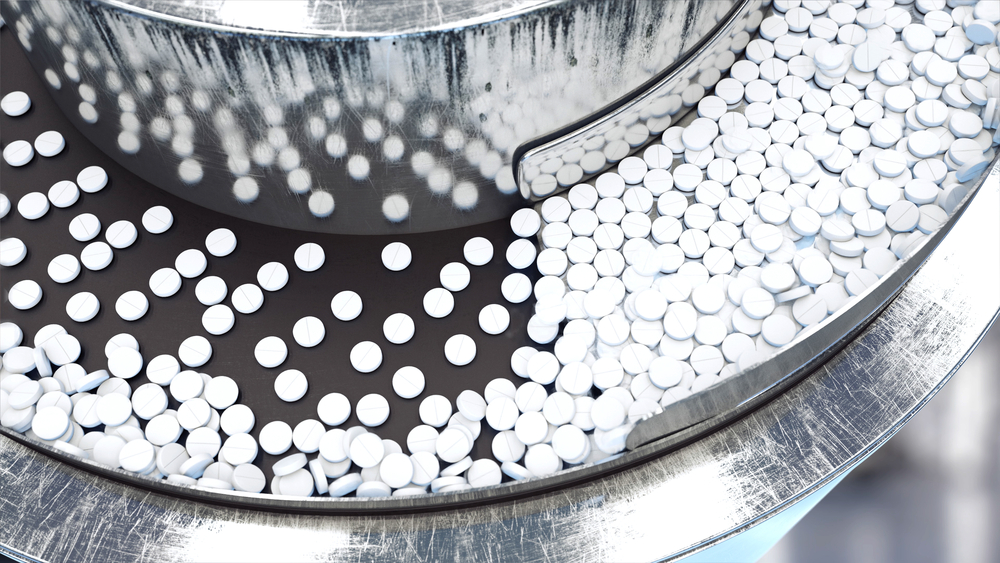

Roto-Disc serves several industries with custom-built industrial valves. We’re going to look at these industries and the materials our valves can handle. Industrial Valves for

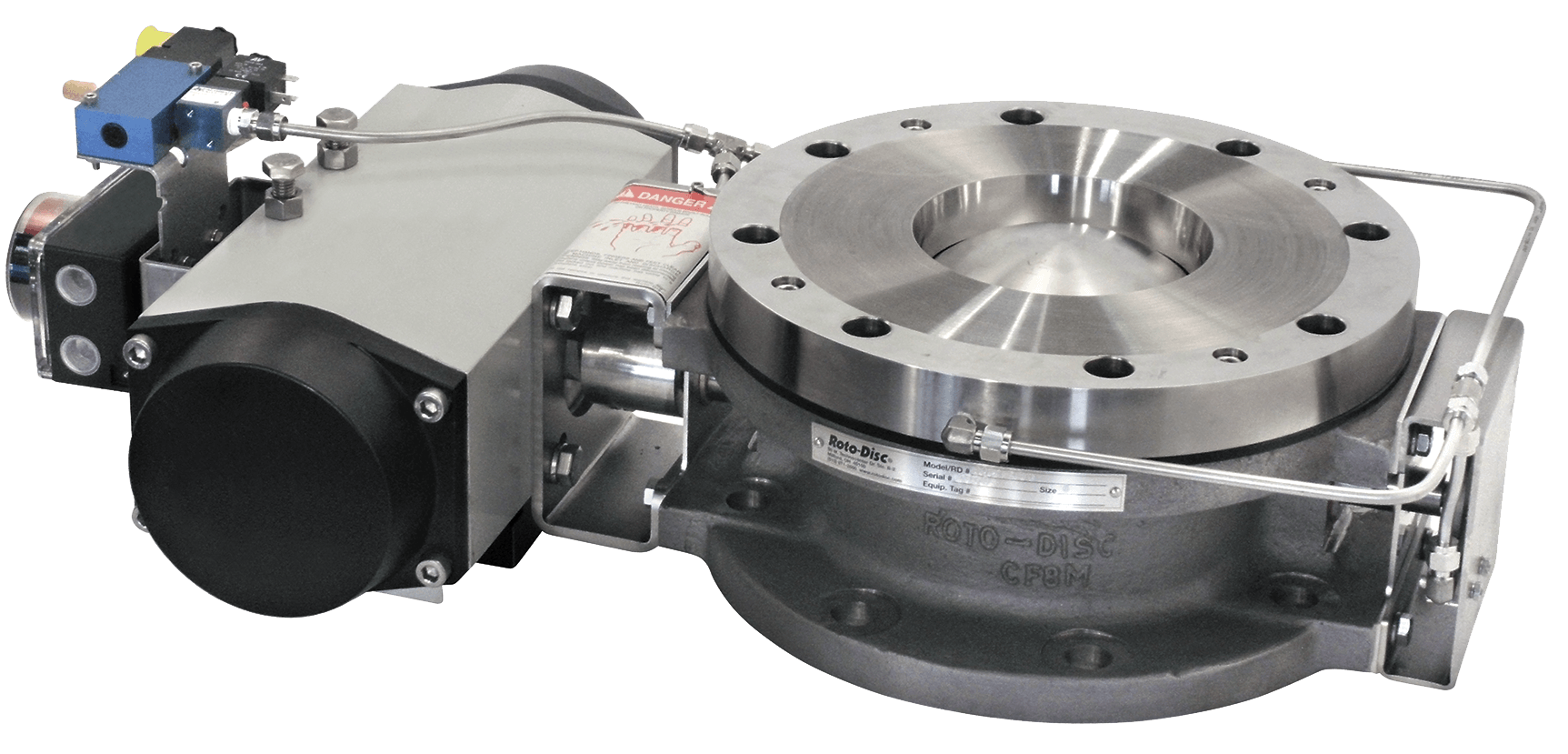

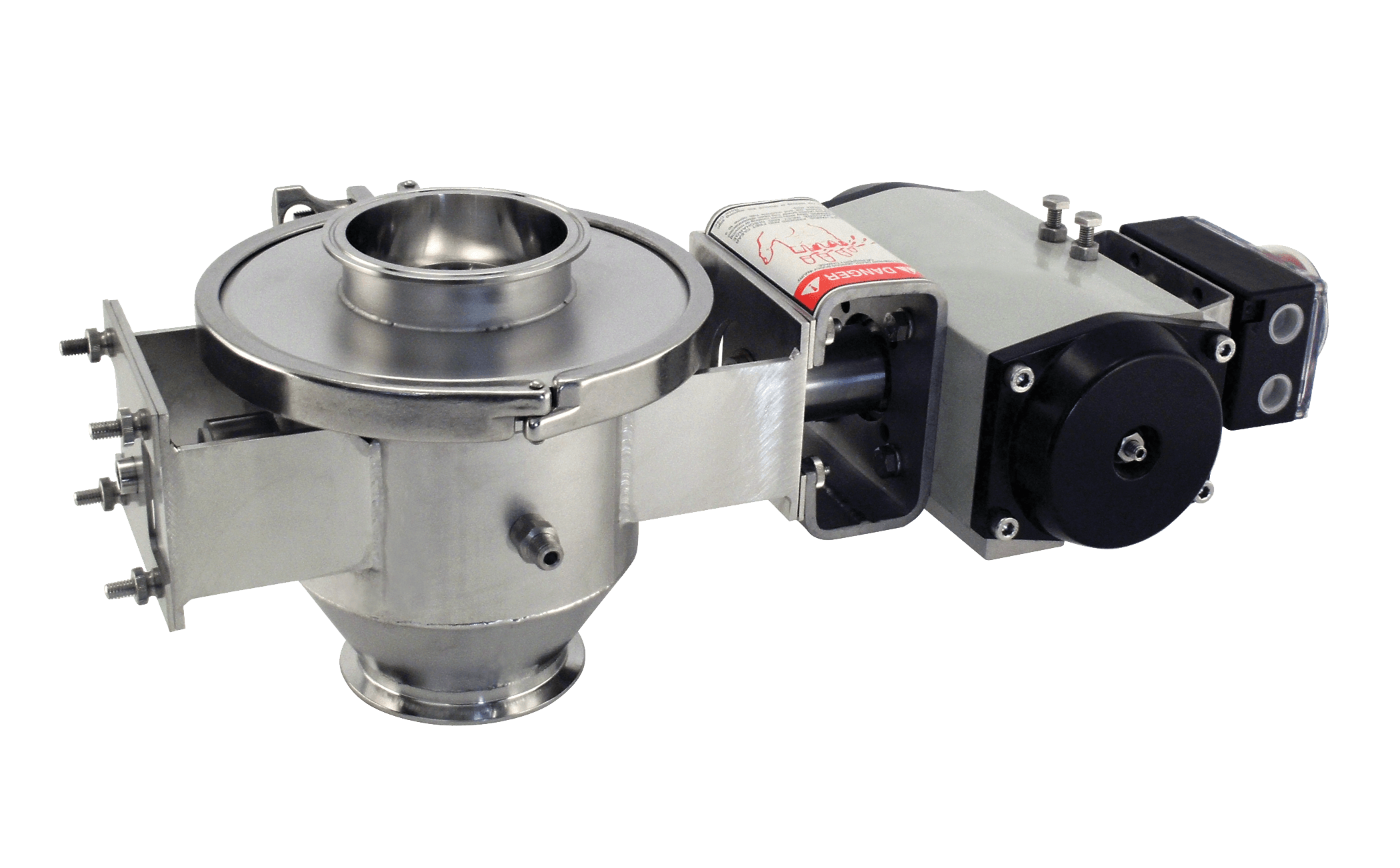

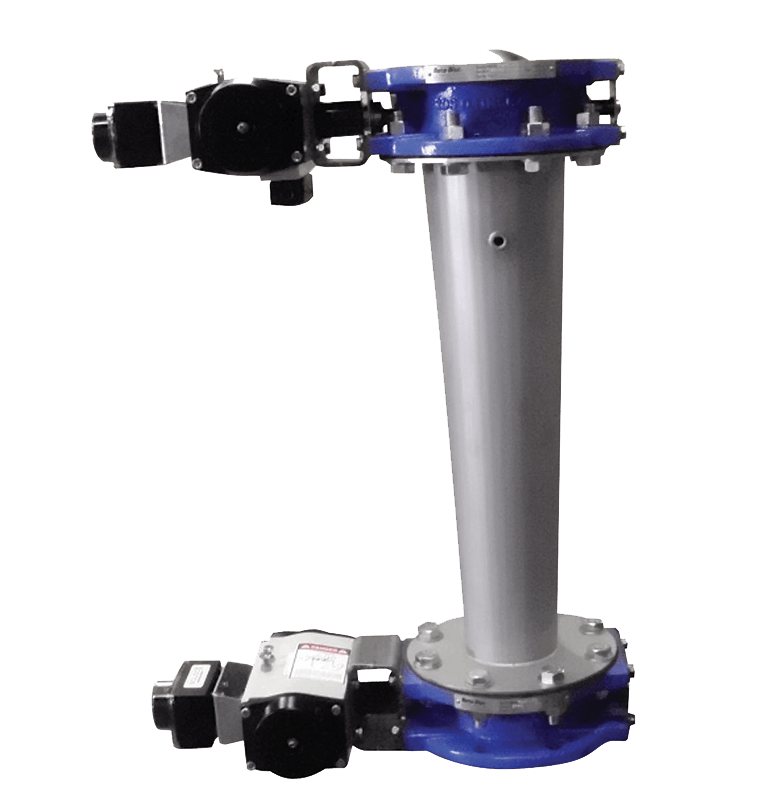

Roto-Disc specializes in state-of-the-art industrial valves for a wide range of applications, from liquids handling to powders, pellets, granules, and chips. Our spherical valves help

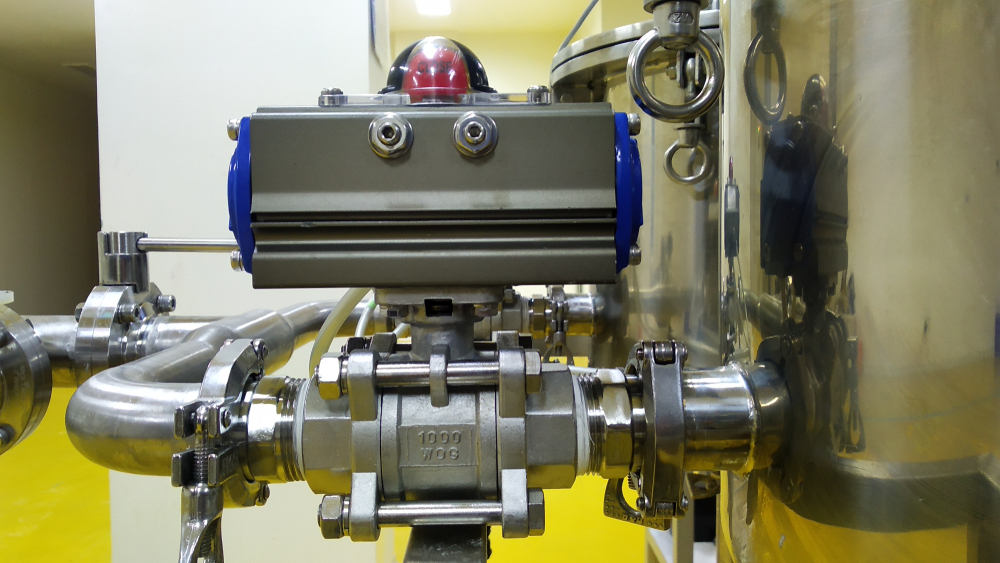

Liquid handling valves represent a necessary component for many manufacturing processes. They offer precise ways to control fluid distribution within your industrial processes, whether you’re

The goal within manufacturing is to create an efficient method of movement for the product being created. Roto-Disc specializes in designing and manufacturing products that

If you are contemplating purchasing a general valve for your system versus a quality custom-made unit, read today’s blog about the benefits of specialty-made products

Choosing the right equipment for a processing plant can be a daunting task, especially given the negative consequences of a valve installation. Luckily, we’re here

Material handling, industrial equipment manufacturing, and the valve industry are all major fields that often go unnoticed by the public. The items used in our

Food and beverage processing is a complex industry that primarily relies on high efficiency to achieve profit goals. Additionally, valves must meet strict requirements to