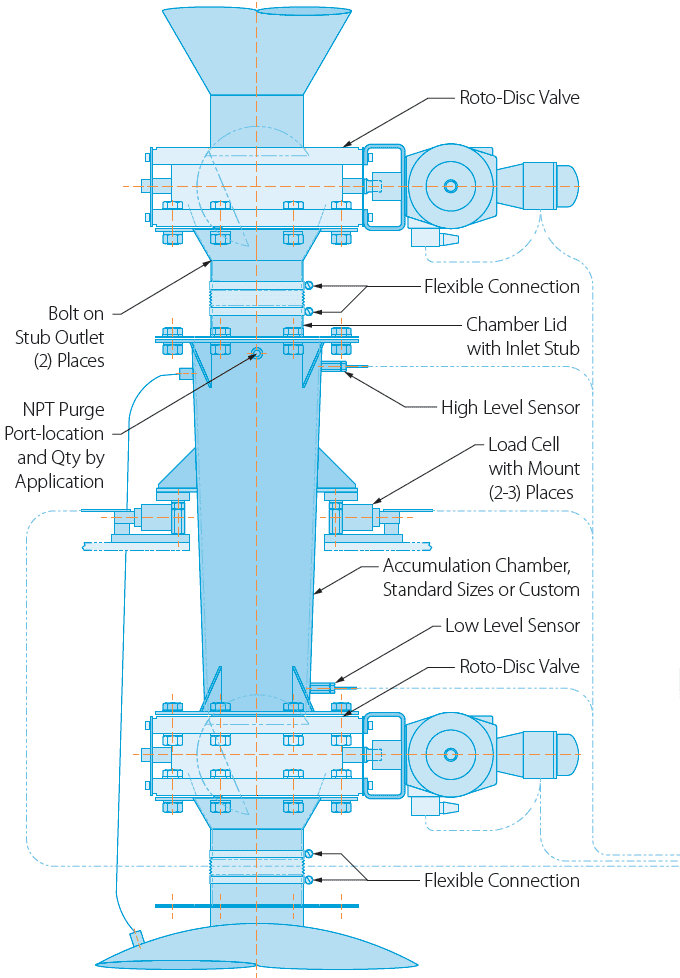

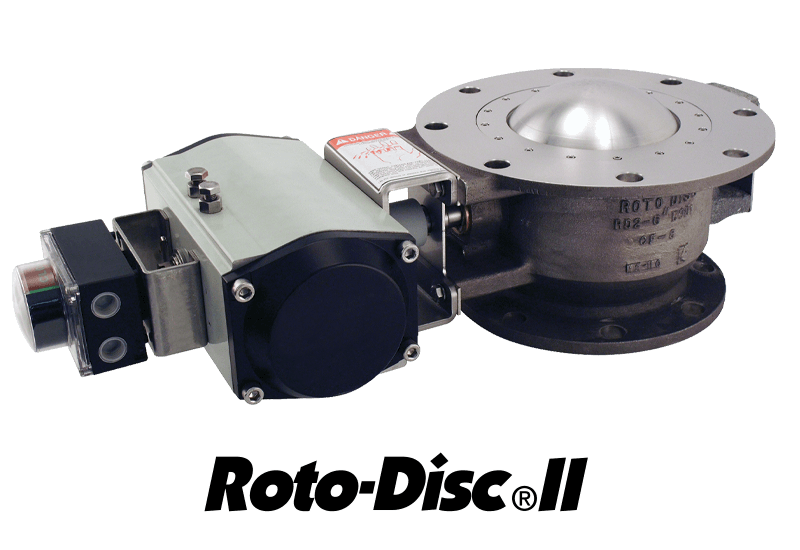

Conquer Material Handling Challenges with Roto-Disc’s Airlock/Double-Dump Valves

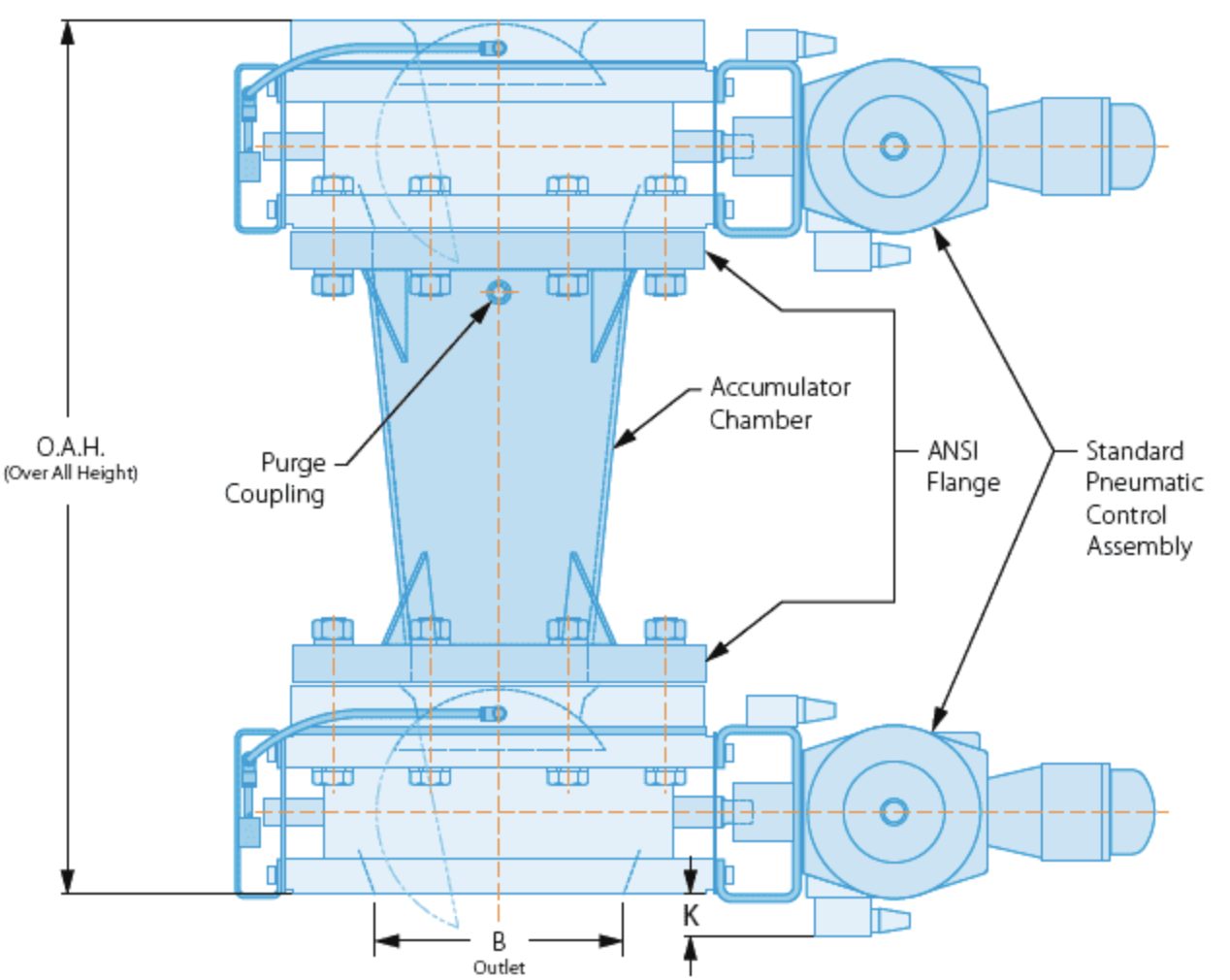

Are you tired of leaky valves and inefficient material transfer in your processing plant? Look no further than Roto-Disc’s innovative Airlock/Double-Dump Valves! The Airlock/Double-Dump Valve