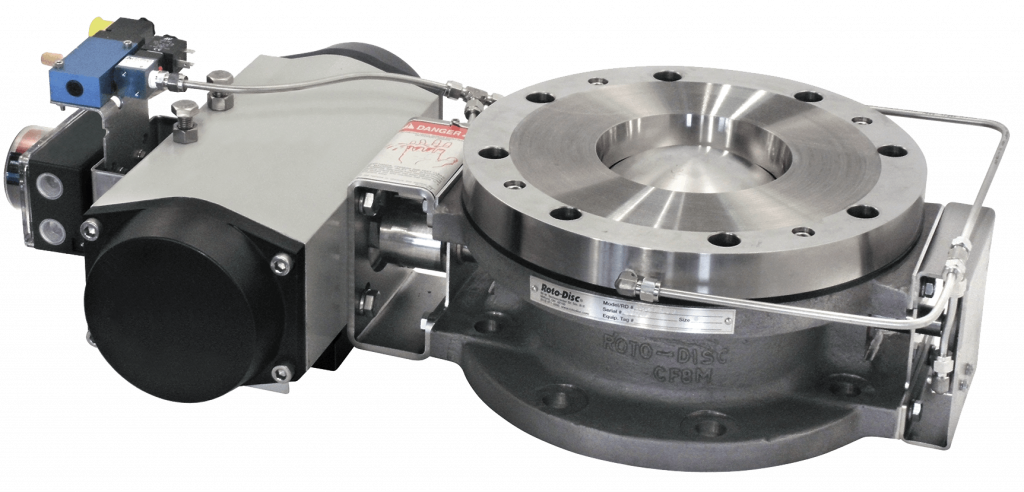

Roto-Disc® Inc’s inflatable seal mechanical interlock system for the Roto-Flate® valve enhances its reliability and causes it to fail closed and inflated in the case of electric or pneumatic loss. The mechanical interlock prevents the inflatable seal from inflating before the valve dome is in the closed position. When utilized with a spring return pneumatic actuator and normally open seal solenoid, the Roto-Flate® closes AND inflates upon electrical power loss, regardless of the position of the valve at the time power is lost.

The interlock also prevents un-intended and/or premature inflation of the inflatable seal, thereby decreasing the risk of damage during start-up. For applications where the valve is required to also close on pneumatic loss, the Roto-Flate® can be provided with a valve arrangement that will inflate the seal from a reserve air source, and keep it inflated for extended periods. Applications that require a fail-open or fail-last disposition can also be easily accommodated upon request. These enhancements allow users of the Roto-Flate® to gain the benefits of its two-stage sealing system while being assured of a known action in the event of electric or pneumatic loss.

Benefits of Roto-Flate® Inflatable Seal Mechanical Interlock System

As a process engineer or plant manager, it is your responsibility to ensure the safety and efficiency of your industrial processes. One way to improve both of these factors is to implement an inflatable seal mechanical interlock system.

Enhanced Safety

The primary benefit of an inflatable seal mechanical interlock system is the superior level of safety it offers. Inflatable Seal valves offer superior pressure-retaining performance because the elastomeric seal compensates for wear and deflection caused by system pressure differentials. They rely on an external control source for proper sequencing of the dome rotation and the seal inflation. Using mechanical interlocks ensures that the seals properly inflate even if the control source fails to sequence the solenoids. When equipped with a reserve air reservoir, they also ensure that the valve properly closes if instrument air is lost.

Improved Efficiency

By ensuring that electrical or plant-air outages don’t result in the valve staying open, mechanical interlocks can prevent batch spoilage and dangerous, uncontrolled process upsets. The system’s ability to lock down automatically also helps to minimize downtime by preventing human error, which would otherwise lead to costly and potentially dangerous mistakes.

Reduced Environmental Impact

Your team will see reduced environmental impact that comes with it. By preventing hazardous materials from leaking or escaping into the environment, your facility can prevent workplace accidents, negative health effects for workers, and possible fines from regulatory agencies due to dangerous leaks.

Applications for Roto-Flate® Industrial Valves

Typical applications are filling and discharging reactors, vacuum dryers, and tanks, or as a shut-off or isolation valve in dense-phase or dilute-phase pneumatic conveying systems. It is available with inlet port sizes 3” through 24” and in a variety of materials of construction to meet application requirements. Also available in air-lock (double-dump) assemblies for air-locking products into and out of sealed environments.

Invest in Roto-Flate® Industrial Valves

Roto-Flate® makes use of an inflatable bladder and provides bubble-tight sealing against full vacuum and pressures up to 150psig. The sealing surfaces are not exposed to material flow, and there is no sliding contact when it opens and closes. Thus it resists abrasive wear and has a long service-life expectancy.

Roto-Disc, Inc., is a world leader in custom valves that make your processes more efficient while reducing labor costs and downtime. Contact Roto-Disc today to learn more about how we can help your company improve its processes and achieve optimal results where inflatable seals are desired.