Roto-Disc specializes in state-of-the-art industrial valves for a wide range of applications, from liquids handling to powders, pellets, granules, and chips.

Our spherical valves help your products maintain purity while reducing downtime due to maintenance caused by common issues like material sticking to parts or wear and tear from faulty vacuum pressure.

Take a look at the top four markets for industrial spherical valves that cater to your processes.

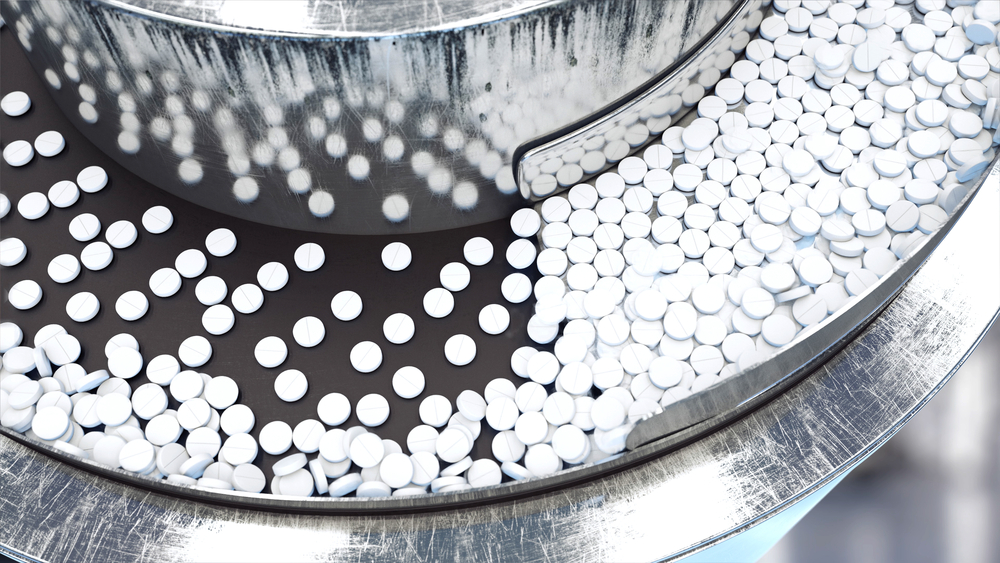

1. Plastics

Plastics manufacturers typically use granules that mix into their liquid polymers for colors. Your industrial process requires precise amounts of granules flowing through your tubes. Otherwise, your plastics have too many or too few colors. Further, you don’t want to waste your supply of plastic granules, especially as supply chain issues or costs rise because of fuel costs.

Spherical valves from Roto-Disc replace outdated butterfly valves for an unobstructed flow geometry that prevents clogs and keeps your production lines moving. Spherical valves also move quickly and efficiently to deliver precise amounts of granules.

2. Food Manufacturing

Your food manufacturing company requires precise measurements of all kinds of ingredients. You might need powdered flour, chips of soybean oil, and granules of chocolate. All three of these classes of substances can make your machinery sticky. As such, you need your ingredient delivery system to maintain precision for quality control.

Spherical valves can replace air-cylinder swing gates that have problems with material adhering to the lip of the plug, which prevents complete closure of the valve. You could lose enough minor ingredients to cause rejects for entire batches of product. Plus, if your power air lines fail, you may face product dumped on the floor.

3. Agriculture

Animal feed and supplements, like food manufacturing, require precise measurements of ingredients to deliver the minimum crude content of protein, fat, and fiber for your feeds. Powders are the typical ingredients for pellets and granules for feed for livestock.

Roto-Disc spherical valves open and close properly as your ingredients blend in industrial mixers. They will reduce clogs and maintain precise amounts of ingredients going into the main batch.

4. Pharmaceutical

Pharmaceutical companies require clean rooms for powders they mix into their final ingredients. And of course, they must absolutely have pure ingredients for efficacy. There can be zero contamination.

Our spherical valves open and close exactly as you need. This prevents contamination while delivering precise amounts of powder. Spherical valves prevent the aggregation of powders on the seals, which lowers your maintenance costs and keeps your systems running smoothly.

Roto-Disc Solves Many Leakage Problems With Spherical Valves

Do your traditional butterfly or swing gate valves leak? Do you need more maintenance time and downtime because of this issue?

Contact Roto-Disc today to learn more about how our spherical valves can help your industrial processes.