Material handling, industrial equipment manufacturing, and the valve industry are all major fields that often go unnoticed by the public.

The items used in our homes are items that first came as raw materials, which required sorting and processing into the products we use today. Roto-Disc is a major part of this process.

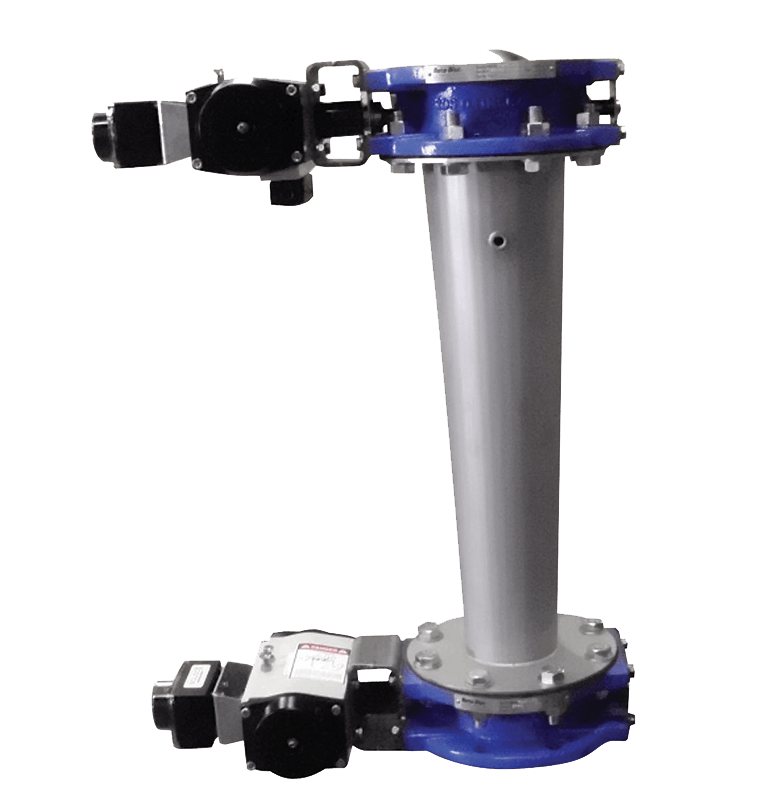

In today’s blog, Roto-Disc discusses why double-dump valves improve material handling.

They Withstand Weathering

Double-dump valves allow materials to flow in a manufacturing process without backflow of air or gas.

In process environments where a differential pressure exists, rotary valves will often leak due to the gap between the blades and the valve housing. Additionally, the friction created from the rubbing of process media against the blades and housing, making them susceptible to wear and tear regardless of the conditions.

Double-dump valves offer a better alternative to rotary valves in any application where material has to flow from environments under different pressures/atmospheres and where low-maintenance is important.

They Handle Diverse Material

Double-dump valves handle a wide variety of granular materials and can be configured to operate at high temperatures (425°+F).

So, what exactly does a double-dump disc valve do? It is part of a manufacturing process that helps move and sort dry, granular raw material used to make items we utilize in everyday life.

Items included in the conveying process with these valves are:

- Fly ash

- Chemical powders

- Sawdust

- Lime

- Shavings

- Cement

- Clinker

- Sinter

- Sand

Most of the above items are recognizable as materials used to construct the infrastructure of our society. Buildings, roadways, and waterways are prime examples of structures built from the above materials.

Efficiency

Being able to handle high amounts of dry material with a lowered impact on wear and tear is highly efficient.

Using a double-dump valve will save money compared to the number of replacements you would need for other valve types. Small changes like this are what ultimately save your company the most money in the long run.

Related Post: Roto-Disc Airlock and Double-Dump Valves With Revolutionary Feeding & Measuring Capability

Contact Roto-Disc for More Details

If you’d like to learn more about the cost-saving benefits that come with investing in custom-designed valves, contact Roto-Disc today. We’ll gladly put you in touch with our valve experts and engineers to discuss specialty valve solutions that are right for you and your business.