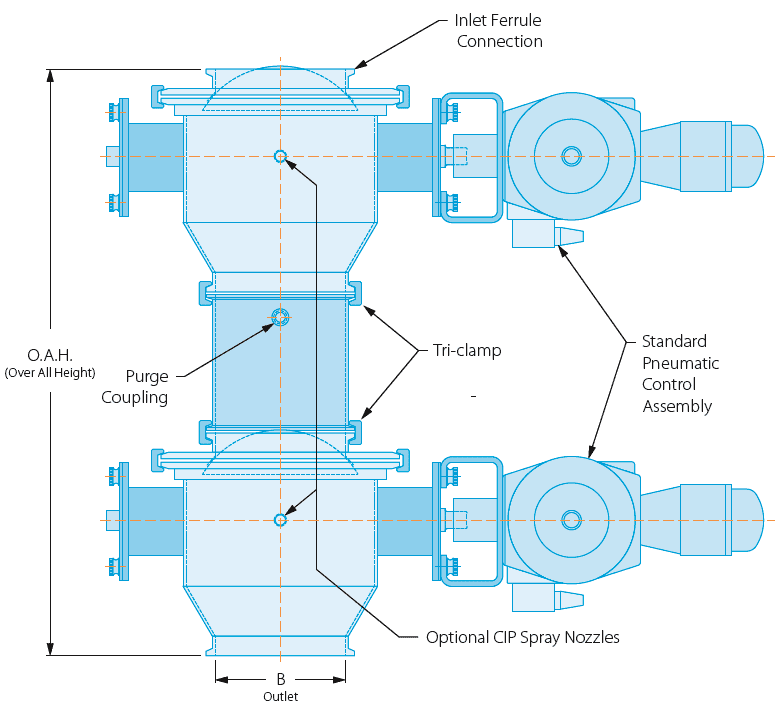

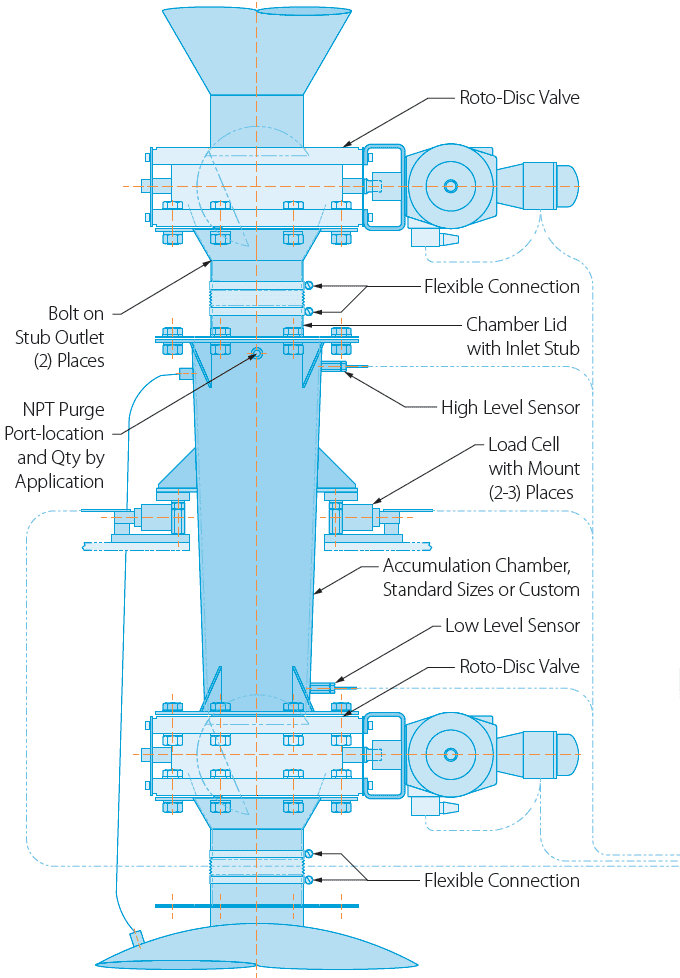

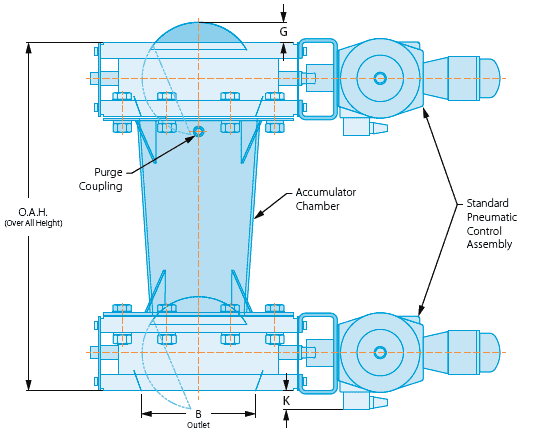

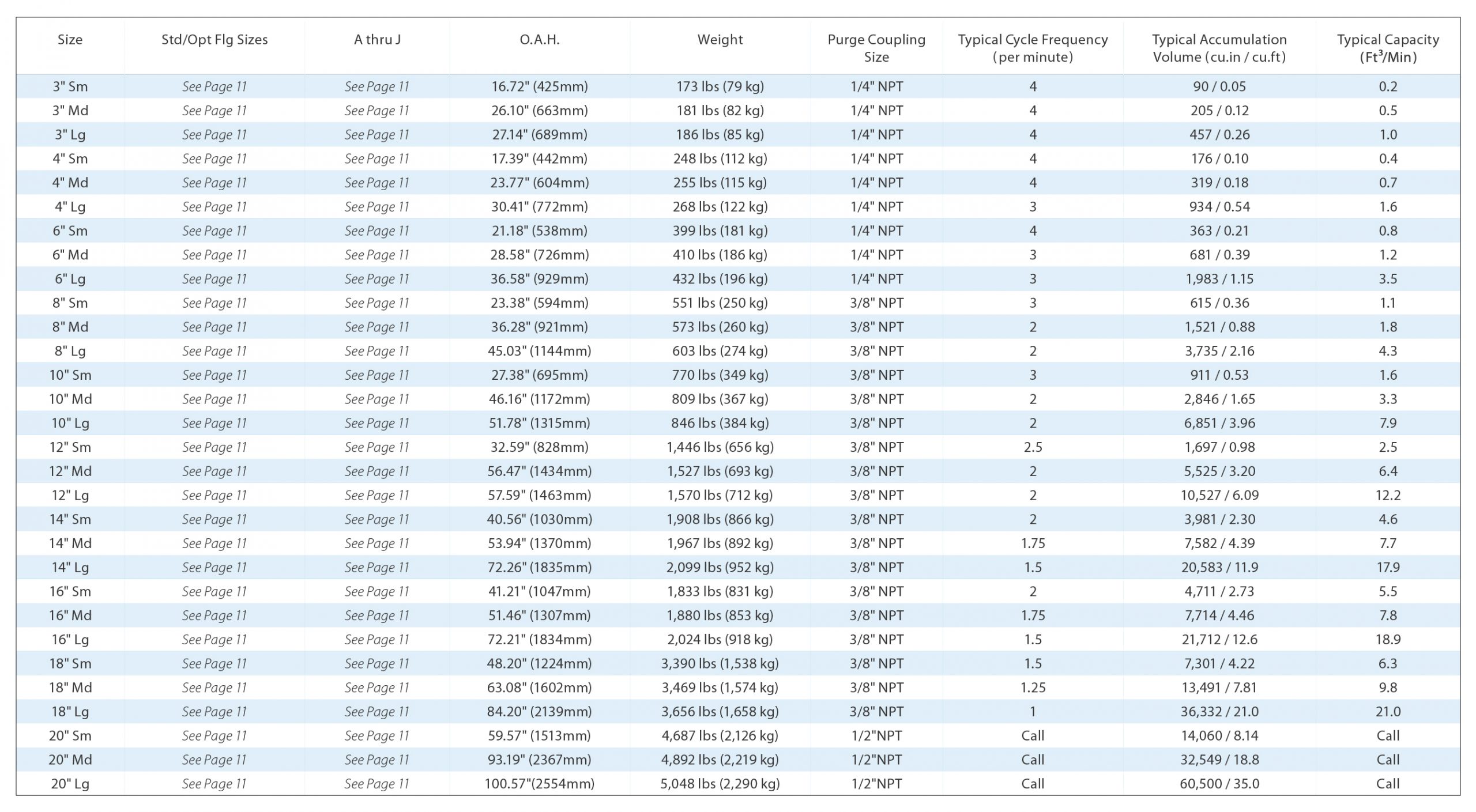

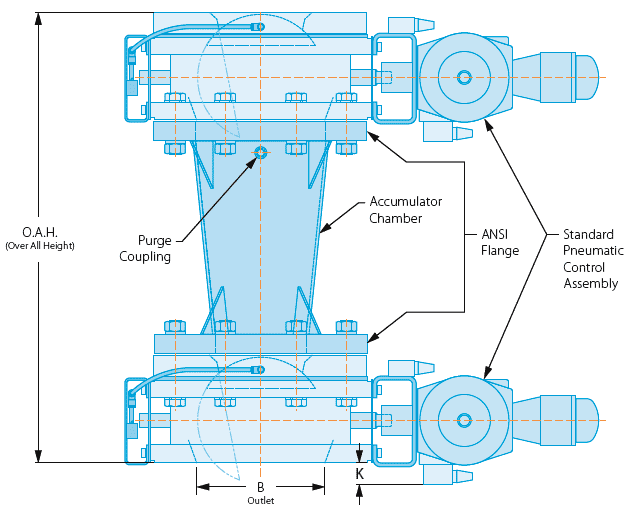

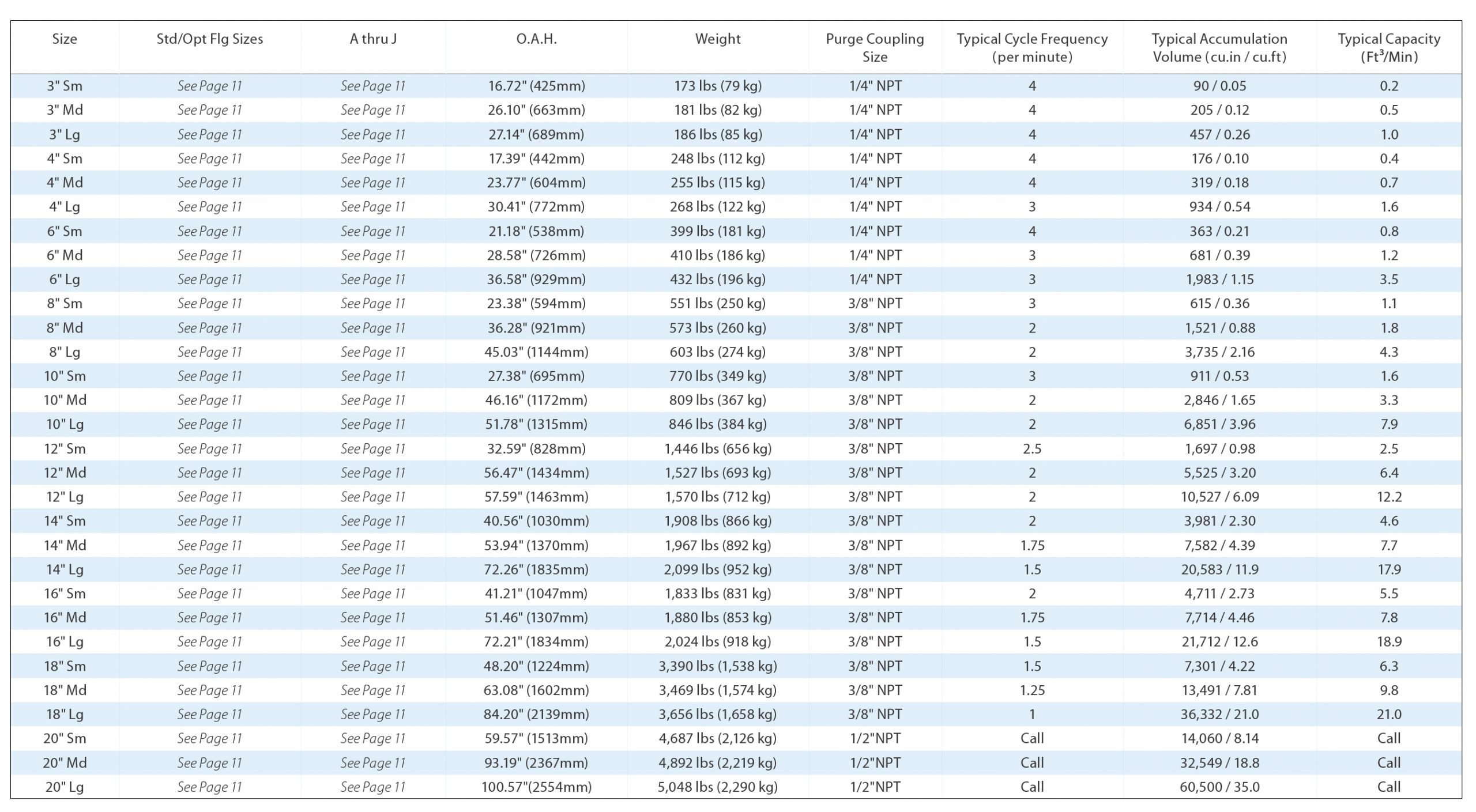

Accumulator chambers can be sized to suit your processing needs.

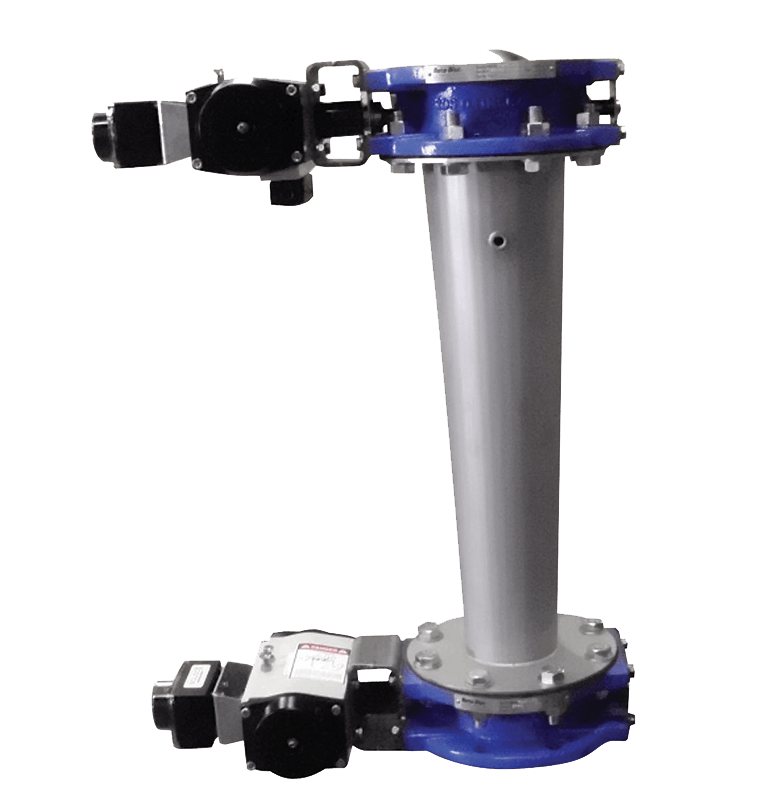

Feed Hoppers & Funnels are available per customer requirements. Assembly supports supplied through engineering partners.

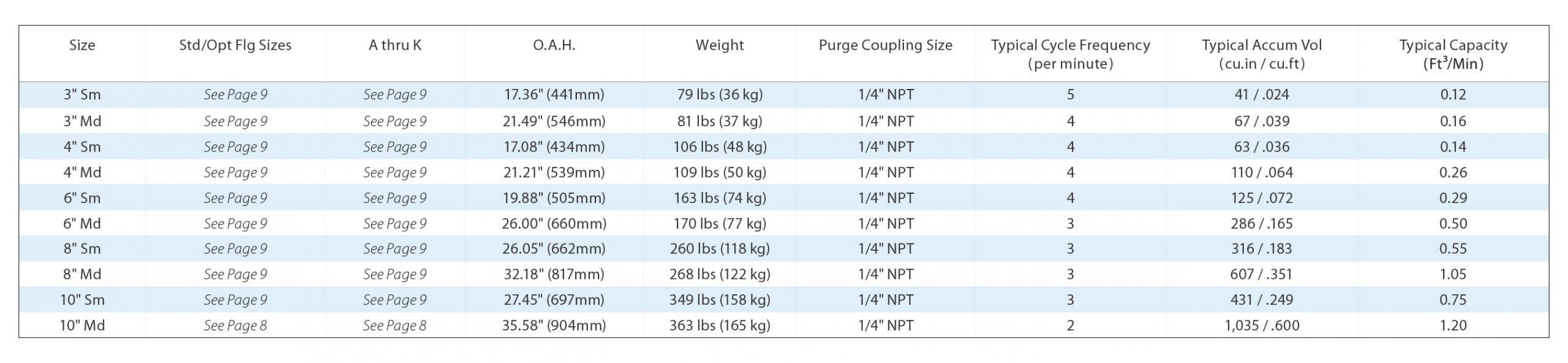

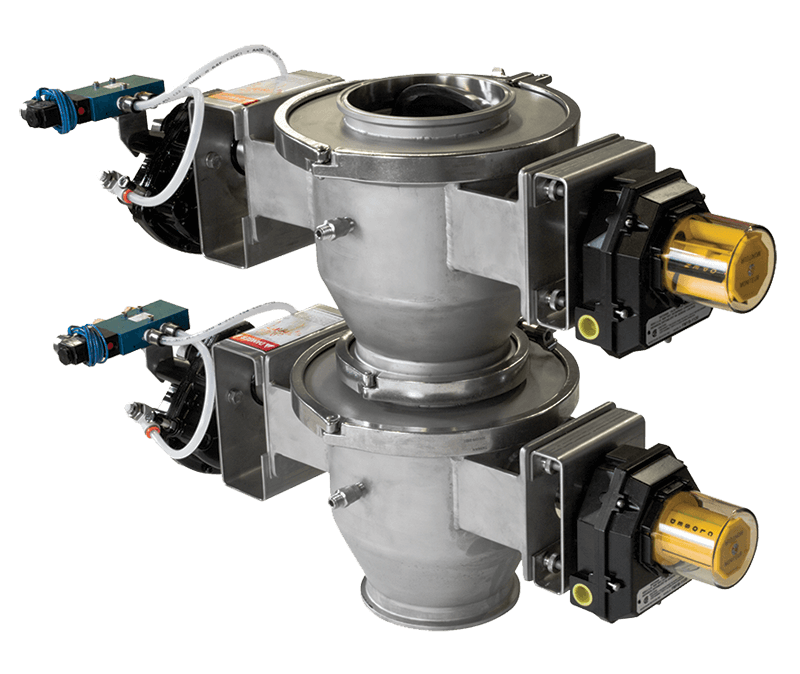

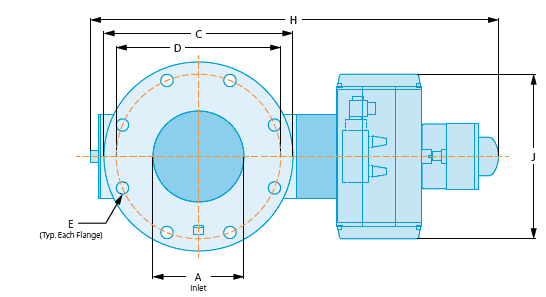

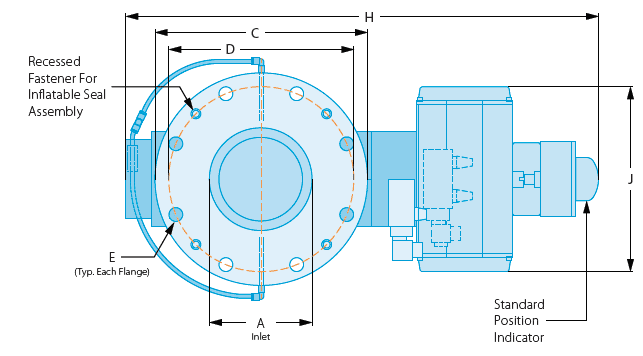

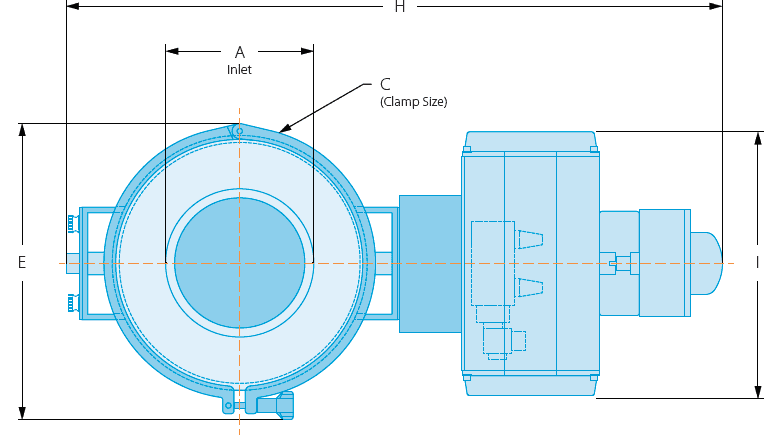

Roto-Disc® Airlock/Double-Dump valves are the solution for processing dry or slurry material into or out of pressure or vacuum environments. Intermediate accumulator chambers are designed for ledge-free flow of material from valve to valve. Cycle-timing and pressure equalization

couplings are available for turn-key feeding solutions. These are the perfect replacement for leaky rotary-vane valves or other, flimsy double-dump valves.

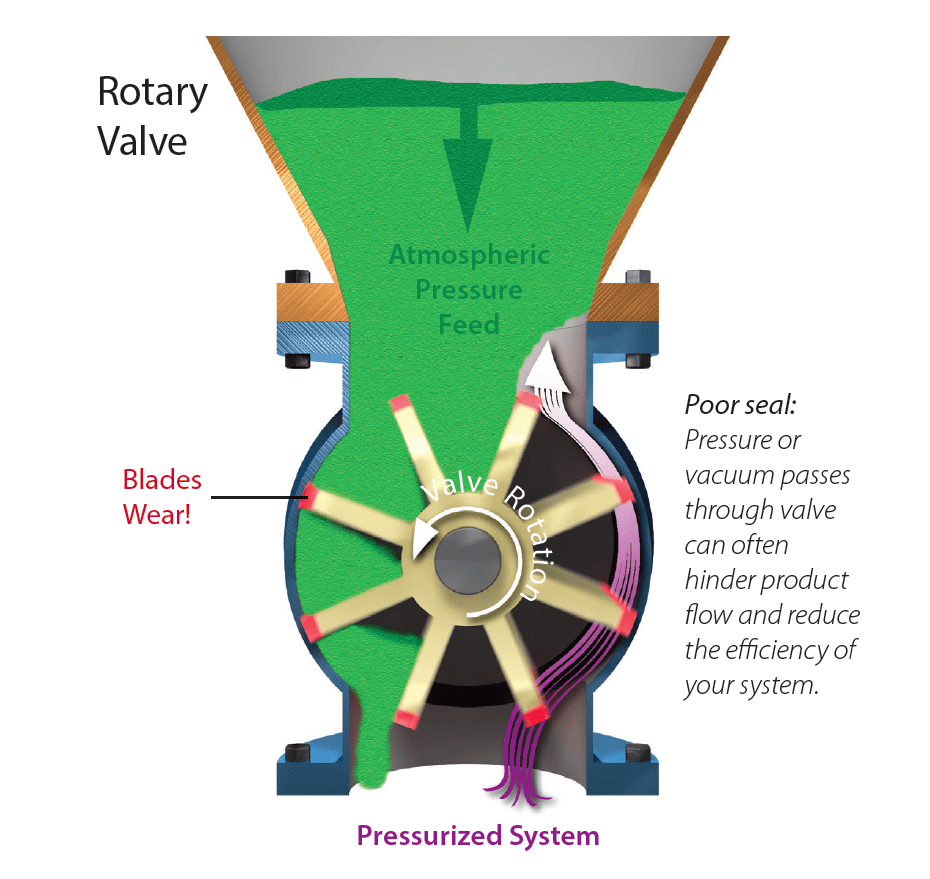

Rotary valves have a gap between the blade ends and the housing that allow leakage. The constant scraping of material between the blade and housing causes even hardened surfaces to wear-out.

This Roto-Disc® valve design takes double-dump valves to the next level. Our double-dump assemblies can be used to process material into/out of differential pressure environments by timing, weight or volume. This is a revolutionary processing solution that can take the place of other feeding devices and make your process more efficient!

The Roto-Disc® Cycle Controller (RDCC)™ allows you to easily control your double-dump assembly to get the throughput you want. Purpose-driven programs, all with manual override, may be saved for specific recipes/batch sizes.

Custom intermediate accumulator chambers to meet a specific volume and/or take-out space requirements are available.

Custom intermediate accumulator chambers to meet a specific volume and/or take-out space requirements are available.

Custom intermediate accumulator chambers to meet a specific volume and/or take-out space requirements are available.