Pneumatic Conveying Calculations Every Engineer Should Know

The right calculations help engineers predict air velocity, pressure drop, and flow rate—factors that determine whether material moves smoothly or a system clogs before it

The right calculations help engineers predict air velocity, pressure drop, and flow rate—factors that determine whether material moves smoothly or a system clogs before it

Struggling with wear or leakage in your airlock system? Roto-Disc compares double-dump and rotary airlock valves to find the best fit for your material handling needs!

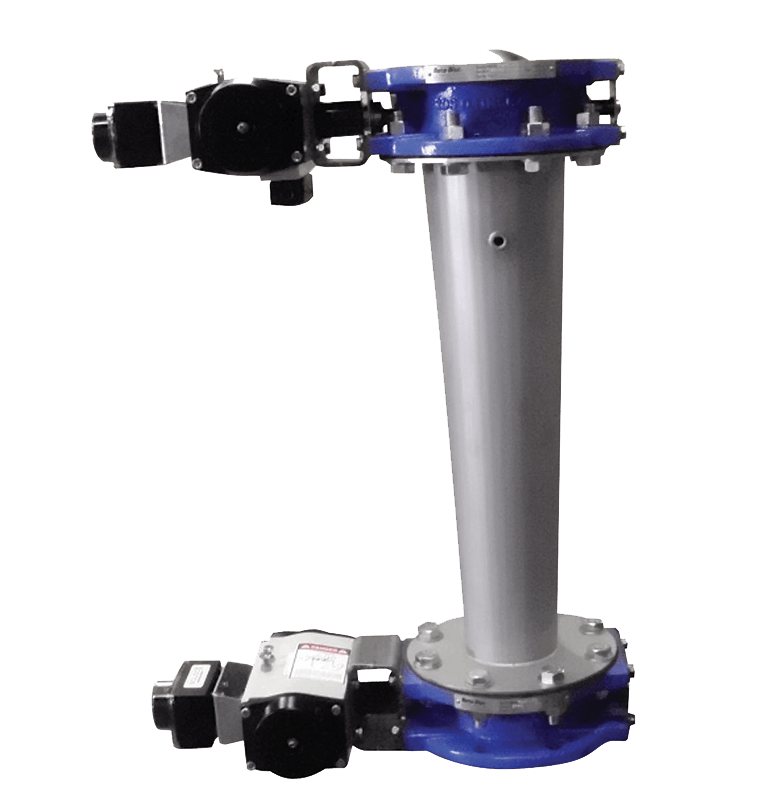

Industrial processors count on rotary valves—also known as rotary airlock valves—to meter powders or slurries between vessels operating under different pressure or vacuum conditions. However,

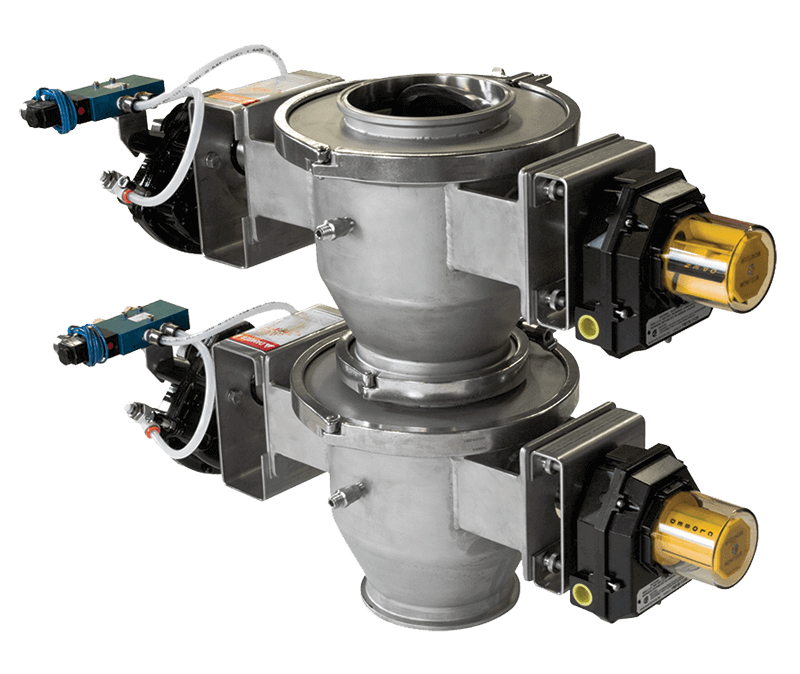

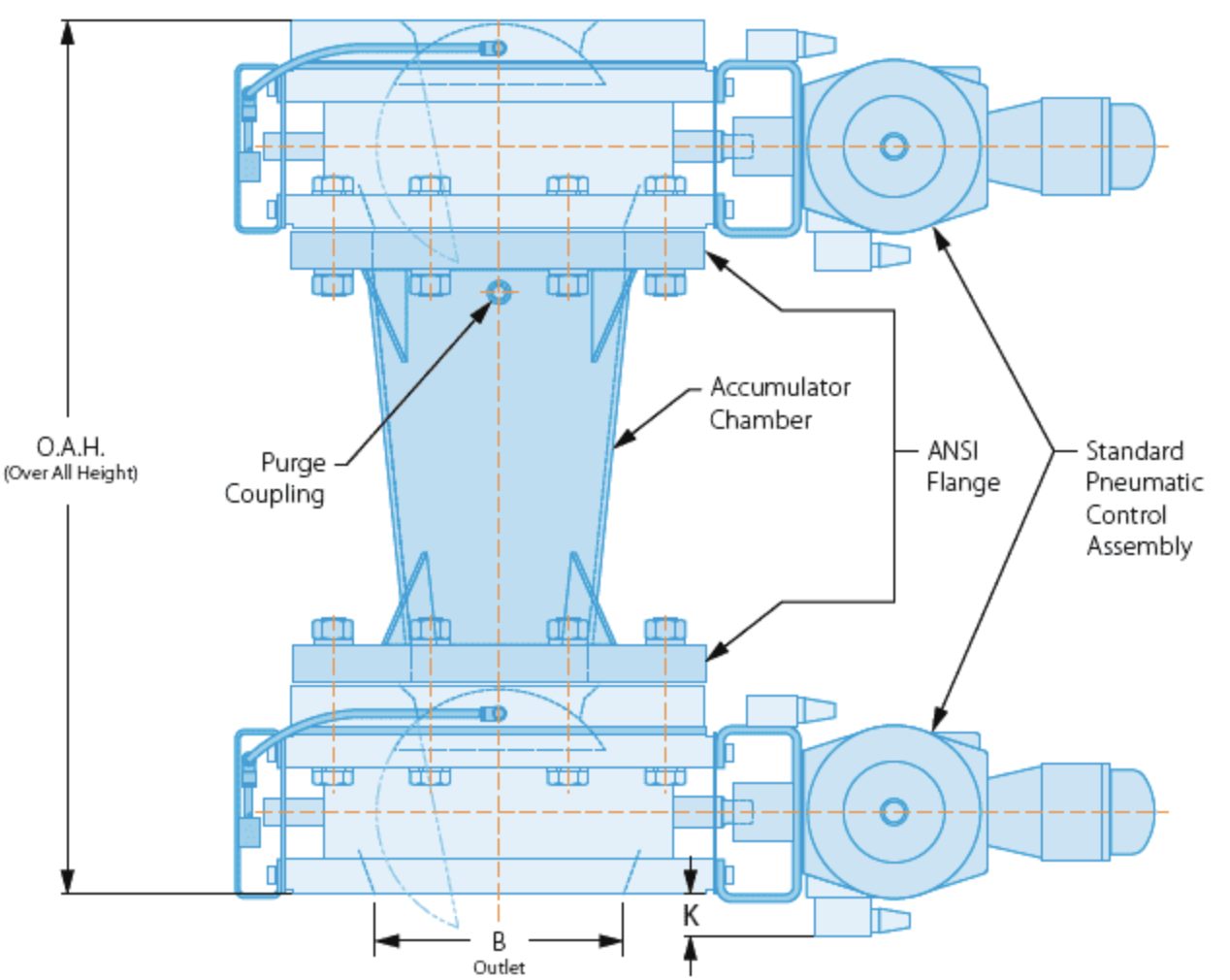

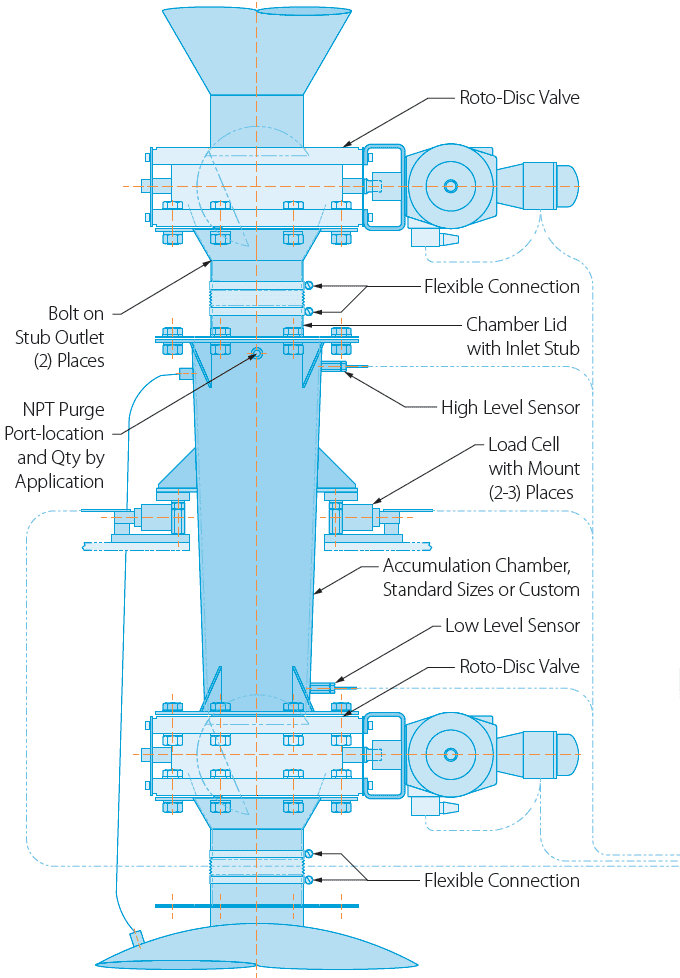

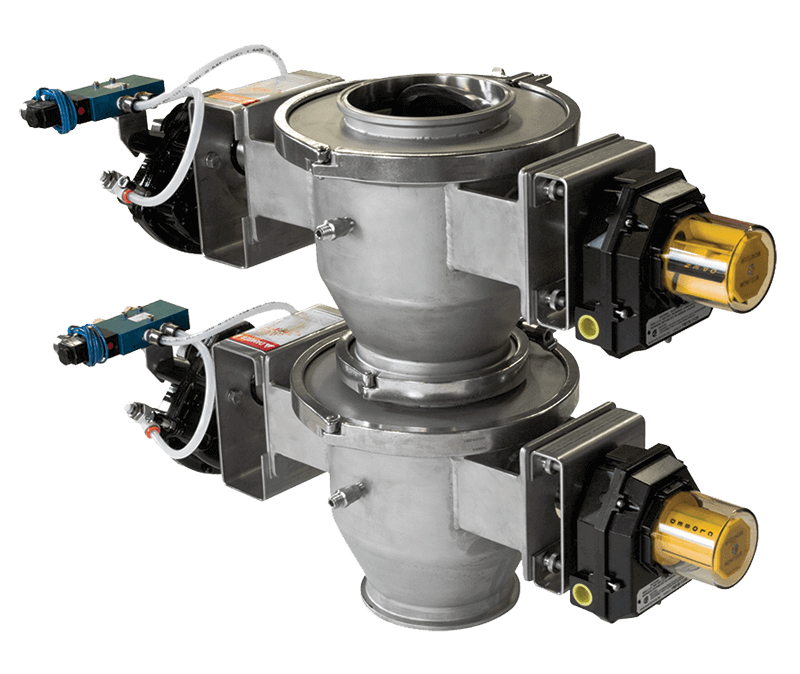

Are your leaky rotary-vane valves or flimsy double-dump valves not cutting it anymore? Airlock/double-dump valve assemblies from Roto-Disc, Inc. offer a solution. Our team specializes

Are you tired of leaky valves and inefficient material transfer in your processing plant? Look no further than Roto-Disc’s innovative Airlock/Double-Dump Valves! The Airlock/Double-Dump Valve

The gap between the ends and the housing of traditional rotary valves allows leakage. Your industrial processes need reliable and efficient material handling solutions. Our

Roto-Disc® airlock/double-dump valves have several advantages over other valve placements, including rotary valves, for your industrial processes involving dry or slurry material. Find out why

Airlock valves are essential to industries like agricultural processing, plastic resins, chemical manufacturing, and many others. They are typically used to process dry materials between

Roto-Disc, Inc. Airlock/Double-Dump valves are now able to feed and measure product into and/or out of pressure or vacuum environments with multiple modes of control.