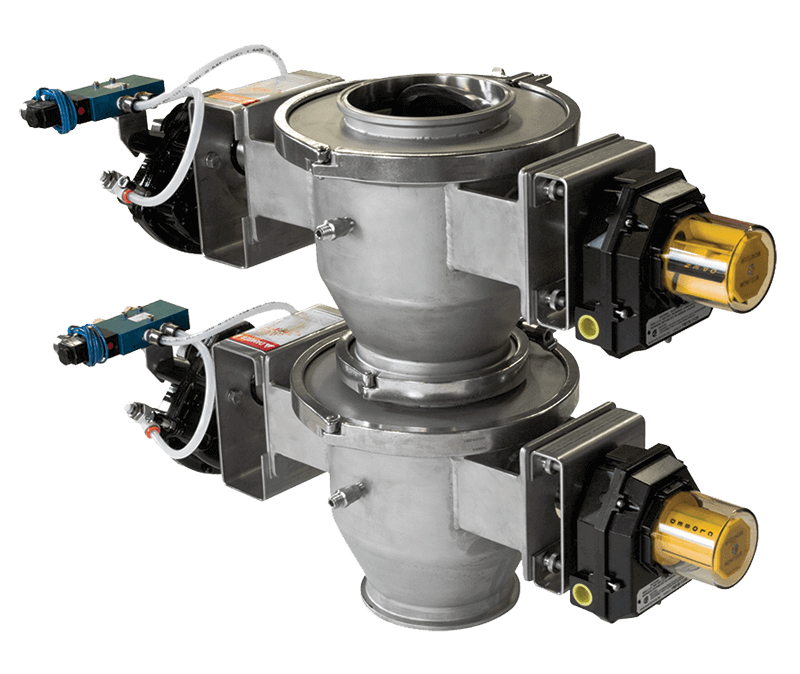

Roto-Disc offers airlock/double-dump valve assemblies as a solution for processing dry or slurry material into and/or out of vacuum and pressure environments.

The overall goal is for unobstructed flow of material from valve to valve without gas pressure leakage across the seats or outside the valve.

Our solution provides the ideal replacement for leaky rotary-vane valves or flimsy double-dump valves while solving problems inherent with traditional rotary airlock valves.

1. Clogging

Rotary valve assemblies are prone to clogging, which often leads to frequent cleanings. Pressure and friction caused by the rotation of the blades in the rotary valve can also create larger particles. When enough of them accumulate on the sides of the housing, it can block product flow which can cause a bad batch.

Roto-Disc’s double-dump airlock valves prevent clogging by removing the parts that cause it. With Roto-Disc Airlock/Double-Dump valves, there’s nothing in the flow stream to obstruct product flow. You’ll have a cleaner process airlock for longer periods of time.

2. Poor Seals

Air pressure and vacuum that passes through the valve can hinder product flow, which reduces the efficiency of your system. Over time, inconsistencies in throughput become evident. Most times, poor seals are apparent even when the valve is new. At best, the rotary valves can be rebuilt. But eventually, you’ll have this same problem again.

Upgrading to a Roto-Disc Airlock/Double-Dump valve eliminates the poor seal because there are no rotary blades. Rather, Roto-Disc provides a way to process dry and slurry material, even those with poor flow characteristics, without losing system pressure.

3. Worn Blades

No matter how good your rotary valves are, the blades will wear down eventually. Overuse, misuse, too fast of a rotation, or faulty repairs and adjustments can lead to blades wearing out even faster.

Worn blades result in excess air leakage, which affects the amount of product that moves through the system. This leads to poor product performance or faulty batches. Your production line may halt work for minutes, hours, or perhaps longer.

Double-dump airlock valves from Roto-Disc mitigate these problems. There are no worn blades. Rather than rely on rotary valves that have several wear points, double-dump airlocks minimize wear, downtime, and malfunction.

Roto-Disc Solves Many Problems Caused by Rotary Valves

Do your traditional rotary valves leak? Do you have more maintenance time and downtime because of this issue?

Contact Roto-Disc today to learn more about how our double-dump airlock valves can help your industrial processes.