Industrial operations hinge on the precise management of material flow. One component of this is a diverter valve.

What is a Diverter Valve?

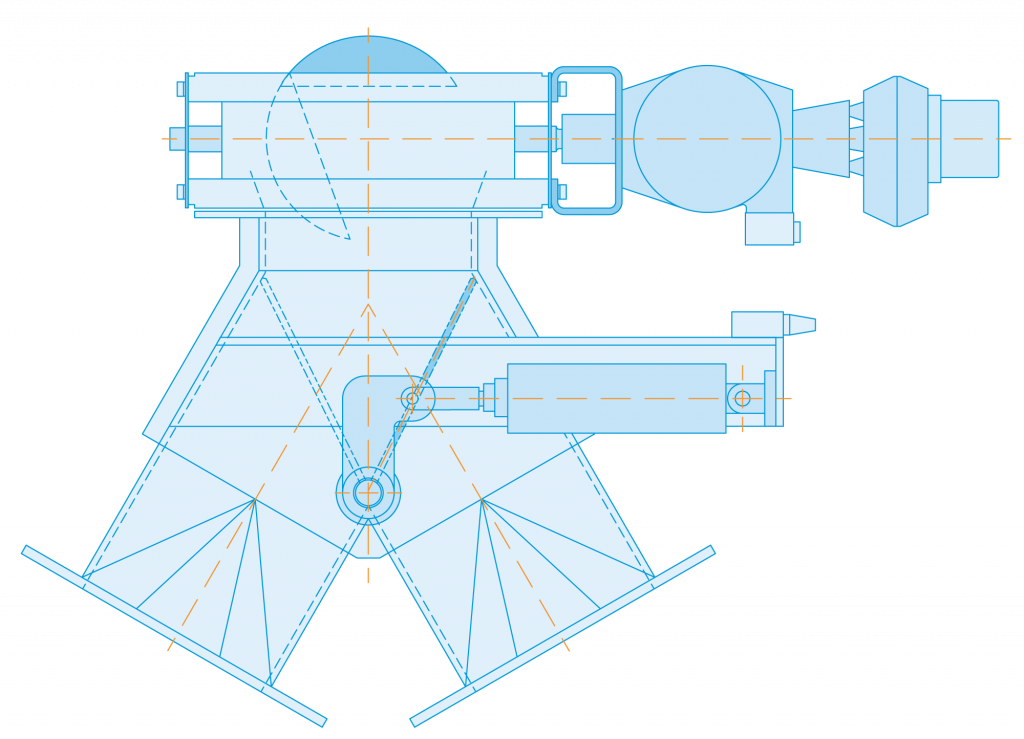

A diverter valve is a mechanical device used to control and redirect the flow of materials within pipelines. This valve functions like a switch, letting operators direct materials toward different paths or destinations.

Related Post: Choosing the Most Effective Solids Handling Valve on the Market Today

Two types of diverter valves are the inflatable seal diverter valve and the blade-type diverter valve.

- Inflatable Seal Diverter Valve

The inflatable seal diverter valve, such as Roto-Disc’s Roto-Vert-Flate, operates with an inflatable bladder, sealing off one path while allowing material to flow through another.

This design ensures a tight seal, preventing cross-contamination and ensuring efficient material handling.

- Blade-Type Diverter Valve

The blade-type diverter valve, such as the Roto-Blade™, uses rotating blades to direct material flow. These blades can swiftly switch positions to guide materials toward the desired outlet, offering precise control and minimal material loss.

Diverter Valves vs. Blow-Off Valves

Diverter valves primarily redirect material flow within pipelines, ensuring efficient routing.

For example, in a food processing plant, a diverter valve might direct different ingredients to mixing tanks, allowing for precise control over the production process.

Blow-off valves are designed to release excess pressure from systems, thereby safeguarding equipment and maintaining operational safety.

Related Post: How Do You Size a Pneumatic Conveying System?

An example of this would be a pneumatic conveying system, where a blow-off valve releases built-up pressure, preventing damage to the equipment.

What Applications Are Diverter Valves Used in?

Diverter valves are used extensively across industries due to their versatility.

Related Post: 10 Industries Our Custom-Built Industrial Valves Help With Improved Equipment

Some common applications include:

- Food and beverage: Diverter valves transfer ingredients, ensuring precise dosing and blending in food processing operations.

- Pharmaceutical: Diverter valves enable the separation of different product streams to prevent contamination.

- Chemical processing: These valves are integral to chemical processing plants, where they enable the diversion of materials for different reactions or treatments.

- Bulk material handling: Industries such as mining and construction rely on diverter valves for the distribution of materials.

Contact Roto-Disc For Industrial Diverter Valves

Do you need diverter valves to optimize your industrial processes? Contact us at

(513) 871-2600 to discuss your requirements and how our diverter valves can elevate your operations.