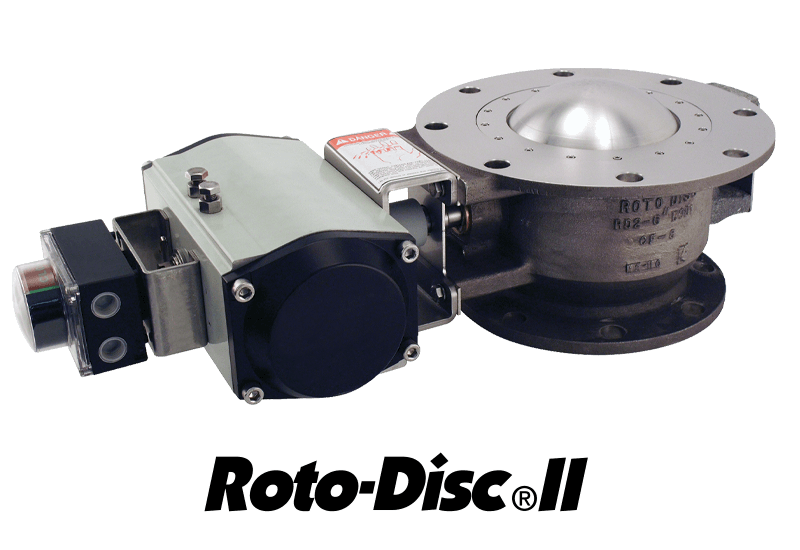

The Roto-Disc II valve with outlet flange that is common to the valve size offers an ideal environment for applications where the valve outlet has to mate to a downstream flange that matches the valve’s inlet orifice.

When provided with an optional inlet flange adaptor, the Roto-Disc II can mate to common ANSI 150# flanges on both the inlet and discharge side, eliminating the need for flange and piping transitions while maintaining a full-orifice valve solution. You’ll save money and time on your current setup.

Why Upgrade to a Roto-Disc II Valve?

This valve maintains all other essential features of the original Roto-Disc valve. All spare parts are interchangeable with equivalent-sized Roto-Disc valves.

The Roto-Disc II slices through material build-up and wipes itself clean with each cycle. The sealing surfaces are not exposed to the flow of material, and there are no hidden places inside for material to build up, making sure nothing sticks and nothing collects material, which could make the interior hard to clean.

Applications of the Roto-Disc II Valve

Typical applications of the Roto-Disc II valve include:

- Hopper Fill & Discharge

- Blender Discharge

- Loss-in-weight feeder re-fill

- Bulk-bag unloading

- Other gravity or low-pressure applications

Other Things You Need to Know About the Roto-Disc II Valve Assembly

Take a look at some vital things you need to know about this valve assembly to see if it’s right for you.

Orientation

The recommended orientation of the Roto-Disc valve is ‘dome-up.’ In some applications, it may be beneficial to install the valve in the ‘dome-down’ position. Consult Roto-Disc, Inc. before installing the valve in the dome-down position.

Temperature Rating

The temperature rating for an individual valve depends on a variety of application conditions and features of the valve.

- Typical Temperature Range: -25°F to 425°F

- Maximum Temperature Range: -40°F to 1,200°F

Pressure Rating

The pressure rating for an individual valve depends on a variety of application conditions and valve features, including principally the seating type, seat calibration, and direction of applied pressure/vacuum.

- Typical Pressure Range: Full vacuum to 150 psig below the dome

- Full vacuum to 25 psig above the dome

Operation of the Roto-Disc II Industrial Valve

We recommend each new valve be cycled (opened and closed) prior to installation to aid visualization and understanding of the valve’s operation and condition. As the dome rotates open, it may protrude below the bottom flange. Therefore it is necessary to support the body in a way that provides vertical clearance below the bottom flange for the dome to rotate into.

Beacon

The visible beacon on most position indicator models signifies open and closed based on 90° of rotation. When a Roto-Disc valve rotates more than 90° to reach the full open position, the beacon will suggest the valve is not fully open (because the beacon has traveled past the 90° “open” mark) when in fact this is not the case. Beacon indicators are calibrated at the factory to be properly aligned to the closed position. Therefore, the imperfection of the beacon indicator will be exhibited when the valve is in the fully open position.

For example, a Roto-Disc valve requires 100° rotation to travel from the fully closed position to the fully open position. When the valve is fully closed, the visible beacon accurately indicates fully closed. When the valve is fully open, the beacon indicator indicates that the valve is not fully open because the beacon flaps are not accurately aligned in the open position. This is because the beacon is tracking the dome which has actually traveled 100° to reach the fully open position. In this instance, the beacon will show that the valve is 10% off from fully open when in fact the valve is fully open. Contact our team before attempting to adjust actuator stop settings to correct readings in the beacon indicator.

Position Indicator

Position Indicators do not control dome rotation. They indicate valve position (open or closed) by use of micro-switches and a visible beacon which are coupled to the dome rotation. Unless otherwise directed by the customer or specifying entity, Roto-Disc will set switch #1 (or the “top” switch) to make at the full closed position and set switch #2 (or the “bottom” switch) to make at the full open position. The switches will be connected to a terminal strip inside the position indicator housing will have an NPT (female) conduit connection point. If specified, solenoid controls may be wired to the position indicator terminal block for further connection to user’s control source. The position switches are not directly coupled to visible beacons, and thus, they can be set to accurately indicate the open and closed position of the Roto-Disc valve.

Refer to the specifying entity or contact Roto-Disc, Inc. to determine if you require any ranges outside the ones we just listed. See our complete users guide to the Roto-Disc II valve here for setting up the valve, solenoid sequences, pressure testing, and seat calibration.

Invest in Roto-Disc Industrial Valves

Roto-Disc II valves could save time, and hence costs, right away as you look to get advantages over your competition, production, and time to market as our valves are specially designed just for your processes.

Roto-Disc, Inc., is a world leader in custom valves and innovative solutions that make your processes more efficient while reducing labor costs and downtime. Contact Roto-Disc today for specific use cases and to learn more about how we can help your company improve its processes.