Roto-Disc specializes in custom industrial valves, diverters, and airlock valves to improve your manufacturing processes. Many valves, even ones created 30 years ago, utilize outdated construction techniques that don’t foster optimal processes. Ball valves, butterfly valves, rotary airlock valves, or slide gate valves may not be the best choices for your processes.

Read our guide to learn more about the products we offer that make your production lines more efficient while reducing downtime.

Table of Contents

What Is Roto-Disc?

Roto-Disc, Inc. designs and manufactures custom valves, airlocks, and diverters tailored to the needs of companies with dry and slurry material handling lines across hundreds of industries worldwide. Pharmaceuticals, food processing, and chemical processing are just a few of the industries we cater to. Our precision-engineered solutions are built to withstand abrasive environments and ensure reliable performance in demanding applications.

Based in the U.S., all products are designed and manufactured in America. We have been in business for over 40 years.

Industries We Serve

As we stated, many industries benefit from our products. Here are just a few examples of what our engineers can do for your company:

In the chemical industry, our world-class valves can handle challenging materials such as silica gel and titanium dioxide during silo discharge and line shut-off processes. For the pharmaceutical sector, our valves can utilize a vacuum dryer discharge to handle powders. Additionally, food processors use Roto-Disc valves in mixer discharges for substances such as powdered flavorings and cake frosting so ingredients flow smoothly from one holding tank to the next.

Other industries like energy, biofuels, and nuclear waste processing also benefit from Roto-Disc’s advanced valve technology. For example, biofuel producers use our double-dump airlock hopper valves for handling crumb rubber, while nuclear facilities rely on airlock valves for managing uranium oxide powder.

These applications demonstrate our company’s ability to handle everything from abrasive chemicals to delicate powders in highly regulated environments for both efficiency and safety.

Here is a representative, high-level list of the industries we serve at Roto-Disc:

- Agriculture

- Batteries

- Chemical

- Alternative Energy

- Biofuels

- Coal-Fired Energy

- Food Processing

- Glass Products

- Mining

- Nuclear Energy

- OEM Parts Production

- Pet Food

- Petrochemical

- Petroleum

- Pharmaceutical

- Pigments

- Plastics

- Powdered Metals

Roto-Disc® Heavy-Duty Spherical Valve

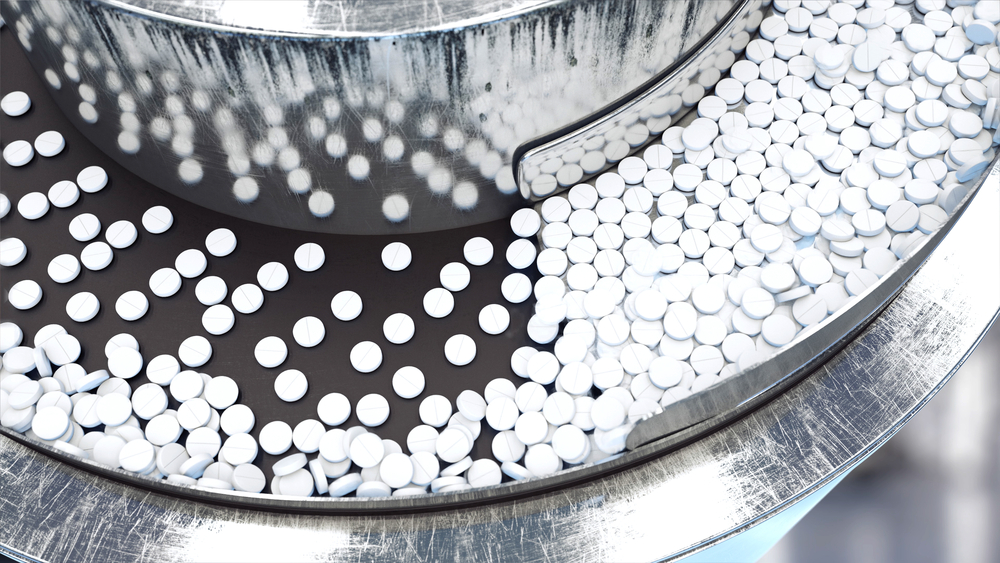

Our Roto-Disc® heavy-duty spherical valve is engineered to handle tough materials such as sticky, abrasive, or gummy substances. Its unique design includes a dome that rotates to slice through the material, avoiding build-up and preventing product leaks. This makes it ideal for industries that deal with challenging materials, such as the chemical or food sector, where powders, pellets, and granules are processed.

An example is in chemical plants where silica or titanium dioxide might cause traditional valves to jam. The Roto-Disc® heavy-duty spherical valve eliminates this issue with its dome-wiping action, which reduces wear and tear while having better production line operation. Additionally, the valve’s high-temperature and pressure-resistance capabilities make it suitable for harsh industrial environments.

Easy maintenance is another significant advantage over other valve placements. With a direct-drive system and a simple seat replacement process, downtime for repairs is minimized. The Roto-Disc® heavy-duty spherical valve can be customized with various materials to meet specific industry demands, while creating durability, efficiency, and longevity in the most demanding applications.

If your company uses ball valves, knifegate/slidegate valves, and butterfly valves, our advanced design can help improve your processes.

![]()

Roto-Disc® II Lighter-Weight Spherical Valve

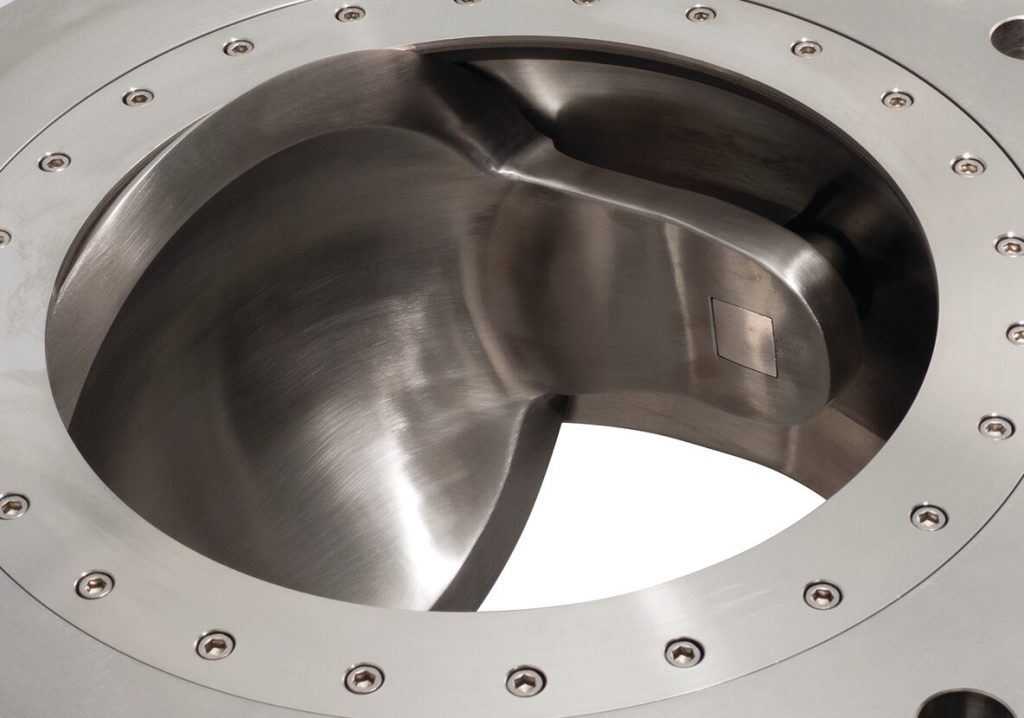

The Roto-Disc® II lighter-weight spherical valve is perfect for applications where weight is a critical factor, offering the same reliability and durability as its heavier counterpart, the original Roto-Disc®, but with a streamlined body. It provides effective sealing and efficient flow control for powders, granules, and other materials in industries such as food processing and pharmaceuticals. The design eliminates product build-up by keeping the flow path clear and wiping materials off the seat as it closes.

This valve is particularly useful in industries that require frequent maintenance or adjustments due to its lighter weight and easily replaceable components. For instance, it’s often utilized in blender or hopper discharges, where consistent material flow is essential. In an application like vacuum dryer discharge in the pharmaceutical industry, this valve ensures that powder-like materials flow smoothly and without obstruction.

The dome’s movement prevents wear and tear found in traditional, outdated valves, reducing the risk of leaks. This valve also minimizes downtime since the valve can be maintained without removing it entirely from the system, providing an efficient solution for processes that prioritize both performance and ease of use. Meanwhile, the varied materials, ranging from stainless steel to advanced alloys, allow the Roto-Disc® II lighter-weight spherical valve to handle a variety of harsh environments.

Roto-Clean® Sanitary Spherical Valve

The Roto-Clean® sanitary spherical valve works best in production lines that require high levels of sanitation and frequent cleaning, such as food processing and pharmaceuticals. It maintains the effective wiping action of the Roto-Disc® valve but includes a body that is easily disassembled by hand in minutes. This design allows for quick cleaning and reassembly without disturbing the valve’s clearances, making it highly efficient for environments that need to handle powders, flavorings, and other sensitive materials.

For instance, the Roto-Clean® sanitary spherical valve is ideal for food production, where powders like spices or flavorings must flow consistently through processing equipment. The Roto-Clean® valve’s stainless-steel dome prevents material build-up so that sticky or powdery substances don’t clog the system. Its construction materials comply with FDA regulations, supporting safe food handling and maintaining product integrity during discharge or flow control.

This valve is also effective in semi-conductor and high-purity silicon industries, where contamination must be minimized. The valve’s easy-to-clean design reduces downtime, while its flexibility in handling different pressures and temperatures makes it adaptable for a variety of industrial needs. It can be mounted in blender discharges, and its lightweight build further enhances its versatility in sanitary applications.

Roto-Flate® Inflatable Seal Spherical Valve

The Roto-Flate® inflatable seal spherical valve handles high-pressure and vacuum environments, offering a bubble-tight seal that prevents leakage of liquids, gases, or dry materials. The inflatable seal prevents sliding contact between the dome and seal, providing efficient and reliable operation in industries requiring pneumatic conveying or vacuum dryer discharge.

For example, in a tank discharge system, the valve’s tight seal and ability to withstand up to 150 PSI prevent product loss during pressure fluctuations. The valve is easy to control, requiring only a simple signal for opening or closing. Its construction from robust materials, such as stainless steel and Hastelloy, ensures long service life and adaptability to extreme temperatures and pressures.

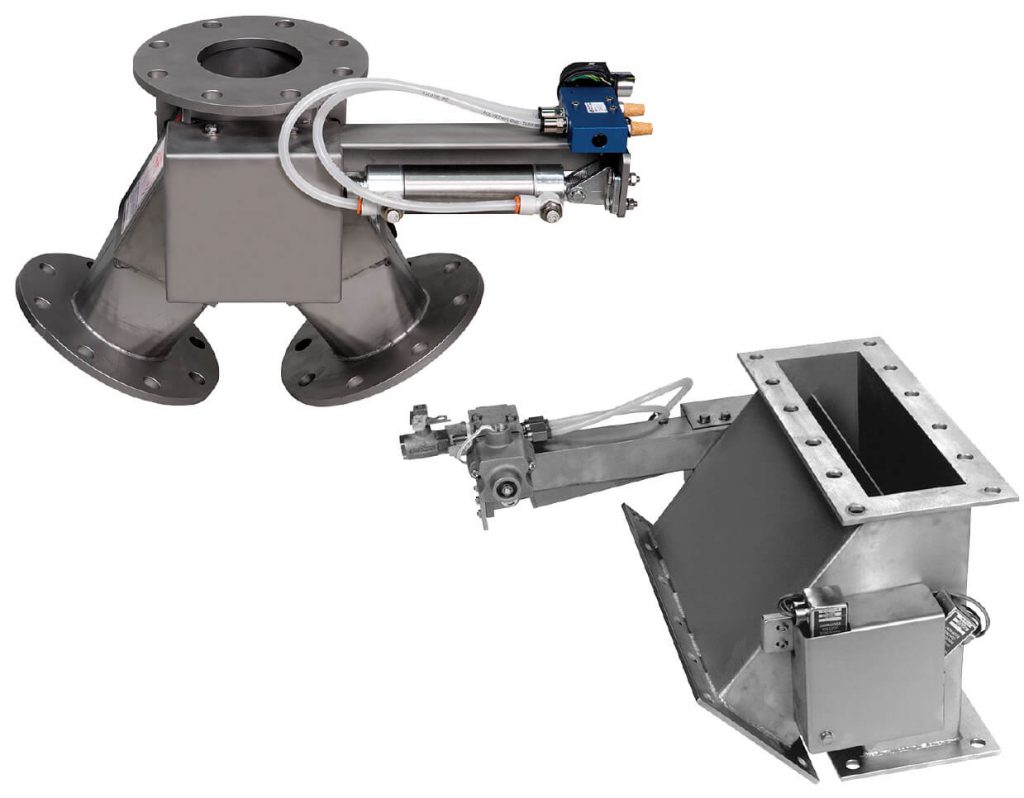

Roto-Blade™ Heavy-Duty Clean-Flow Diverter

Our Roto-Blade™ heavy-duty clean flow diverter represents a specialized valve for diverting material flow in industries handling powders, pellets, or granules. Its precision-machined blade fits tightly against the sidewalls, minimizing blow-by and fostering efficient material flow. The blade is protected from the material stream, preventing wear and tear, while the absence of internal hang-up points makes it ideal for clean environments where build-up can affect batch purity.

In applications like food processing, the Roto-Blade™ diverter efficiently directs powders without clogging. Its removable side plate allows for easy cleaning and maintenance without dismounting, making it both practical and sanitary.

The valve is customizable for various industries, with options for polished internals and tri-clamp connections, further enhancing its suitability for sectors requiring strict hygiene, such as pharmaceuticals and food processing. Its heavy-duty construction provides long-lasting performance in demanding applications, while quick-acting air cylinders enable rapid switching between flow paths.

Roto-Vert-Flate™ Inflatable Seal Spherical Diverter Valve

Our Roto-Vert-Flate™ provides an inflatable seal spherical diverter valve with a bubble-tight shut-off between two environments with high differential pressures. The valve uses the Roto-Flate™ inflatable seal system and a rotating dome that slices through the material, preventing contact with the seat and keeping wear and tear to a minimum.

For example, in dense-phase pneumatic conveying systems, this valve effectively seals off pressure differentials and diverts material flow without requiring two separate valves. Therefore, the Roto-Vert-Flate™ is both space-efficient and reliable in high-pressure environments.

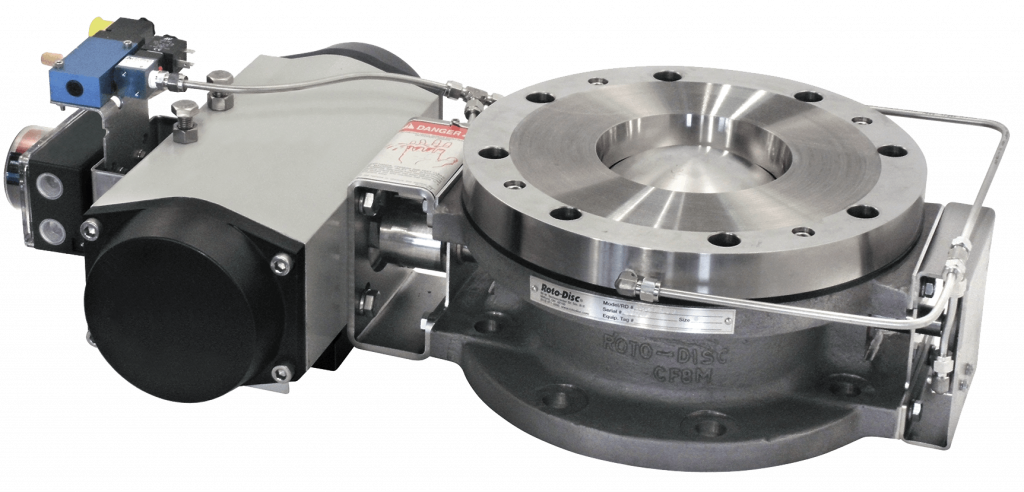

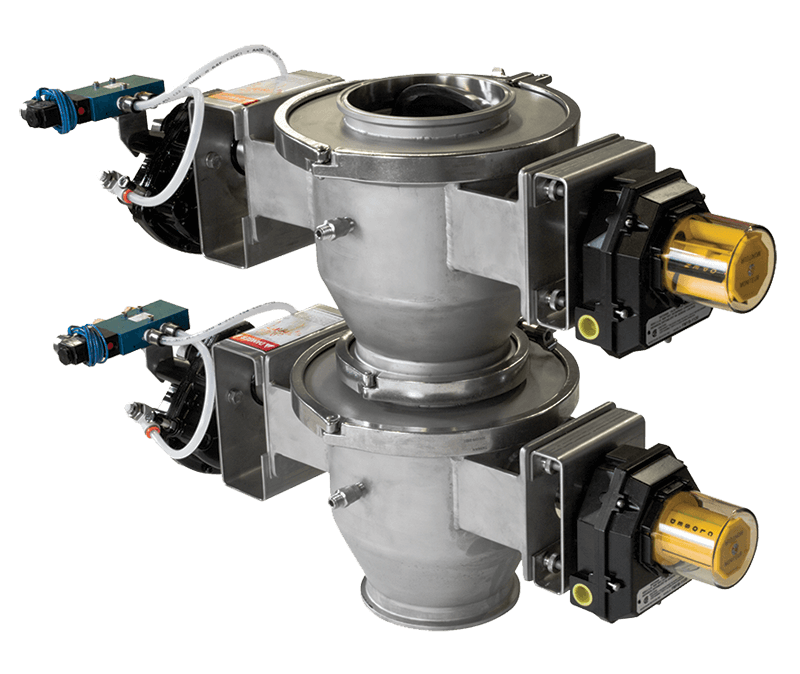

Airlock/Double-Dump Valve Assemblies

Our airlock/double-dump valve moves dry or slurry materials in and out of pressure or vacuum environments by timing, weight, or volume. It features two alternating valves that open and close sequentially, maintaining an airlock and preventing material or pressure leakage.

For instance, in a pneumatic conveying system, this valve can efficiently manage the flow of granular materials like powders or pellets. Its sturdy design and customizable controls ensure seamless integration into industrial processes, reducing the downtime and wear common with traditional rotary valves.

Flange Adaptors

Roto-Disc flange adaptors provide versatile connection solutions for the Roto-Disc® and Roto-Disc® II valves. They can accommodate a wide variety of inlet and outlet options, so that the valves can seamlessly connect to different pipe sizes and configurations.

These adaptors are commonly used in industries where precise and secure connections are essential, such as food processing and pharmaceuticals. For example, in a food processing plant, flange adaptors allow the valves to be easily integrated into existing piping systems, enabling smooth material flow and quick maintenance.

Innovative Solutions

Our innovative custom solutions allow us to tailor valves to your exact requirements.

Crust Breaker Dome

The crust breaker dome is a specialized component designed to manage and eliminate crusting issues in industrial processes. This innovative solution helps to prevent the build-up of material that can cause blockages and operational inefficiencies.

By incorporating a unique dome shape, the crust breaker dome effectively disrupts the formation of crusts for smoother and more reliable material flow. For instance, in a rotary kiln used for cement production, this dome helps maintain consistent throughput by minimizing crust formation that could otherwise halt operations.

Interior Clean in Place

The interior clean-in-place (CIP) system provides a highly efficient method for cleaning the interior surfaces of equipment without requiring disassembly. This solution is particularly valuable in industries where hygiene and cleanliness are paramount, such as food and beverage processing.

The CIP system uses a combination of sprays and cleaning solutions to thoroughly clean equipment, reducing downtime and labor costs associated with manual cleaning. An example of its application is in dairy processing facilities, where the CIP system allows valves for milk tanks to be cleaned efficiently between batches, maintaining high sanitary standards.

Shut-Off Diverter Valve

The shut-off diverter valve is an essential component for controlling the flow of materials within a system. It allows operators to divert or completely shut off the flow of material as needed, providing greater flexibility and control over the process.

This valve is particularly useful in scenarios where precise material handling is required, such as in bulk material handling systems. For instance, in a grain processing plant, the shut-off diverter valve can redirect the flow of grain to different storage silos or shut off the flow during maintenance operations for smooth and uninterrupted processing.

Wedge Inserts

Wedge Inserts are designed to enhance the performance and efficiency of industrial machinery by improving the precision and stability of components. These inserts are used to fill gaps and provide additional support, reducing wear and tear on machinery parts.

An example of their application is in conveyor systems, where Wedge Inserts can stabilize the conveyor belt and reduce vibration, leading to longer equipment life and smoother operation. By addressing alignment issues and reinforcing structural integrity, these inserts contribute to more reliable and efficient machinery performance.

Contact Roto-Disc

Choosing a valve from Roto-Disc is an investment in operational excellence with products made in the United States, factory training from engineers, and improved manufacturing processes for your team.

Contact us today to find out more about our products.