Industrial processors count on rotary valves—also known as rotary airlock valves—to meter powders or slurries between vessels operating under different pressure or vacuum conditions. However, in practice, the component designed to protect throughput often becomes the biggest bottleneck.

Clogging, air leaks, and premature wear quietly drain maintenance budgets and take a toll on product quality.

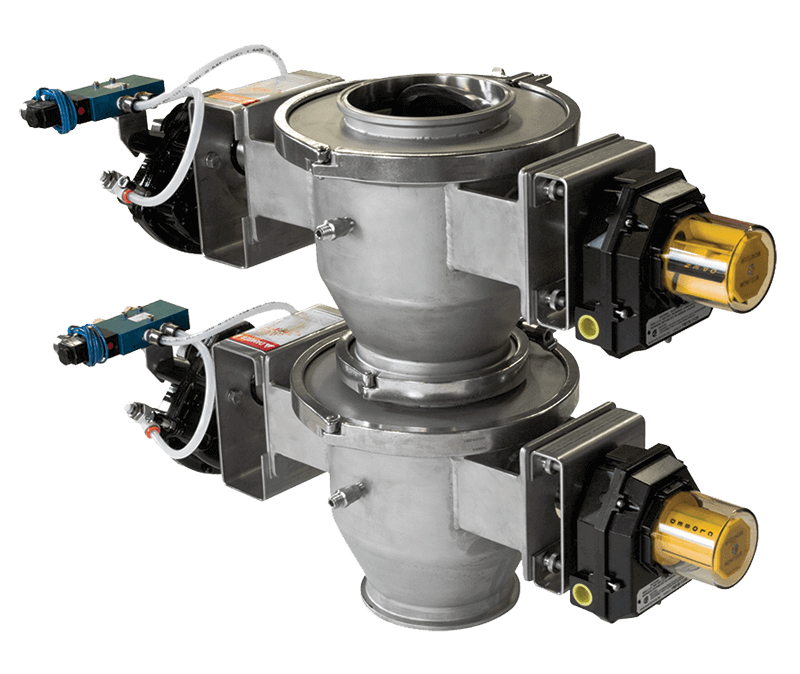

In this blog post, we’ll walk through five common issues engineers face, explain why traditional rotary valves come up short, and show how a Roto-Disc® Airlock/Double-Dump Valve Assembly delivers a simpler, more dependable solution.

The Challenges of Traditional Rotary Airlock Valves

1. Chronic Clogging That Stalls Production

Rotary valves use bladed rotors to push material across the housing. That movement can cause fine particles to smear, clump, or even soften due to friction, especially in powders that are sticky or heat-sensitive.

The result? Material builds up, restricts flow, and sometimes contaminates future batches. As Powder & Bulk Solids warns, trying to open a plugged valve under pressure can even be dangerous.

Roto-Disc® Fix:

Our double-dump design eliminates the need for a rotating element completely. Instead, two spherical valves isolate a small chamber. With no blades to create drag or buildup, material drops through cleanly under gravity.

2. Poor Seals That Waste Energy and Product

To rotate freely, blades in a traditional airlock need clearance, which becomes a built-in leakage path. To maintain steady pressure, plants often crank up blowers or pumps, which increases energy use.

Meanwhile, fine powders can escape and work their way into bearings, leading to costly repairs.

Roto-Disc® Fix:

Spherical seats, machined to tight tolerances—and optional inflatable seals on our Roto-Vert-Flate™—ensure that when the valve is closed, it’s truly sealed.

During each dump cycle, the upper valve seals before the lower opens, keeping pressure zones isolated. Most customers report 25–40% reductions in energy use after retrofitting.

3. Blade Wear That Leads to Downtime

Rotary blades, even with hardened tips, wear down over time. Gaps widen, seals break down, and you risk sending metal fragments downstream—a serious problem in food or specialty chemical applications.

Roto-Disc® Fix:

Our valves use a quarter-turn spherical closure, so wear is limited to two simple seating surfaces. These can be reground in place or swapped out quickly—no shafts, end plates, or tight alignments are needed.

4. Tedious Cleaning and Hard-to-Validate Sanitation

If your process involves switching between flavors, resins, or active ingredients, cleaning a rotary valve becomes incredibly tedious.. Disassembling housings, tracking small parts, and attempting to reach every crevice consume valuable labor time.

Roto-Disc® Fix:

Our ROTO-Clean™ sanitary spherical valve opens fully for tool-less inspection. On our double-dump units, the chamber drops away completely, giving full 360-degree access.

5. Poor Process Control

Standard rotary airlocks spin at a fixed RPM, which can either flood your pneumatic line or starve your reactor. Even with sensors and VFDs, it’s challenging to achieve precise metering due to the slip between the blades and housing.

Roto-Disc® Fix:

We offer optional load cells and level sensors to turn the accumulator chamber into a weighed or volumetric feeder. Pair that with our Roto-Disc Cycle Controller™, and you get real-time control over batch size and feed rate.

How Does a Double-Dump Valve Actually Work?

Now that you’ve seen why so many engineers switch from rotary valves to a Roto-Disc® assembly, let’s take a look at what’s happening inside. The secret to better performance lies in a simple, four-step sequence that replaces constant rotation with clean, controlled movement.

How It Works: The Double-Dump Sequence

Fill

The upper valve opens, while the lower valve remains shut. The product drops into the chamber.

Isolate

The upper valve closes to seal off process pressure.

Dump

The lower valve opens, releasing material into the next stage.

Reset

The lower valve closes, the chamber repressurizes, and the cycle begins again.

Because only one valve opens at a time, your pressure zones stay stable. With fewer moving parts, integration is easy, and wear is more predictable.

Thinking About Making the Switch?

Retrofitting a Roto-Disc® double-dump assembly is more straightforward than most teams expect. Here’s what the process looks like from start to finish.

What to Expect When Planning a Retrofit

Audit the Line:

Map pressure zones, temperatures, and particle size.

Specify Chamber Volume:

Choose from small (0.08 ft³), medium (0.25 ft³), large (0.45 ft³), or custom sizes.

Add Connection Adaptors:

Use Roto-Disc® flanges for easy drop-in replacement.

Program the PLC:

We provide the logic; you adjust dump timing and sensor thresholds.

Validate:

Run leak tests, check dump weights, and compare motor loads.

Concerned about costs? Most systems pay for themselves within 6–12 months, thanks to reduced downtime, lower energy costs, and improved output.

Meeting Industry Standards

If your line involves pneumatic conveying, NFPA 652 and 654 standards for combustible dust may apply. Our double-dump valves help meet those guidelines by sealing tightly and minimizing metal-to-metal friction.

Final Thoughts for Plant Engineers

Rotary valves are commonly used for metering products, but their blade-based design can lead to leaks, wear, and inefficiencies over time. The Roto-Disc® Airlock/Double-Dump Valve Assembly offers a streamlined and durable alternative that addresses these challenges.

Customers have reported significant improvements, including:

- Reduced unplanned downtime

- Enhanced batch control accuracy

- Lower energy consumption

Whether you’re processing abrasive minerals, fine food powders, or corrosive slurries, Roto-Disc® provides configurations tailored to your specific needs.

Solving Rotary Valve Failures with Roto-Disc®

If you’re tired of leaky seals, worn blades, and endless rebuilds, it’s time to upgrade.

When all else fails, we’ll review your current setup, recommend a double-dump retrofit, and show you the ROI using your plant’s actual numbers. Contact us today to get started!