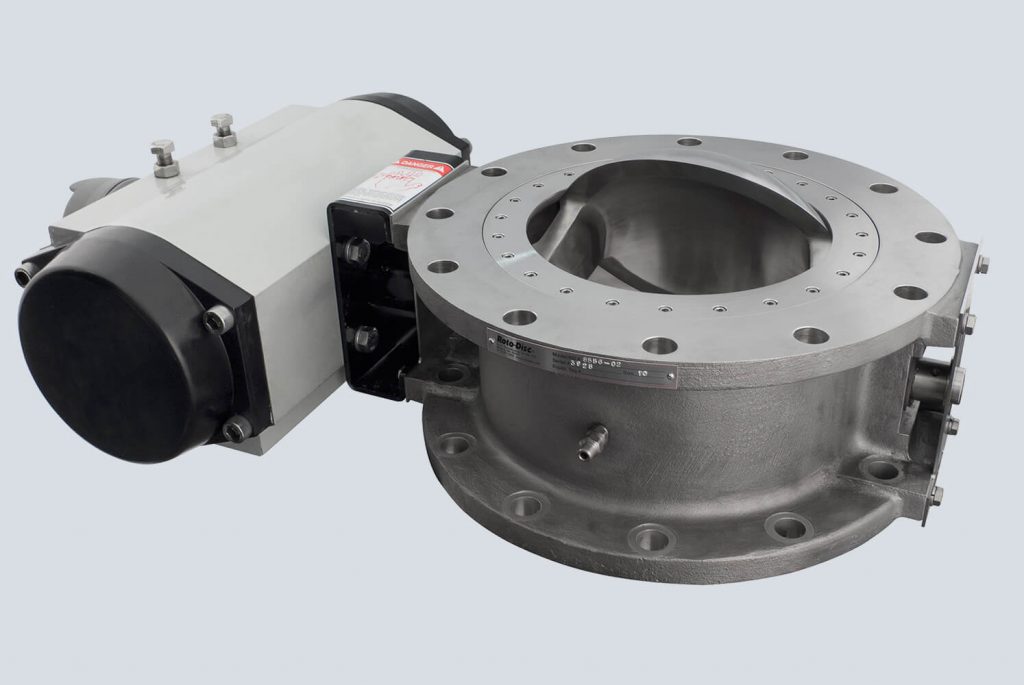

Roto-Disc®, Inc.

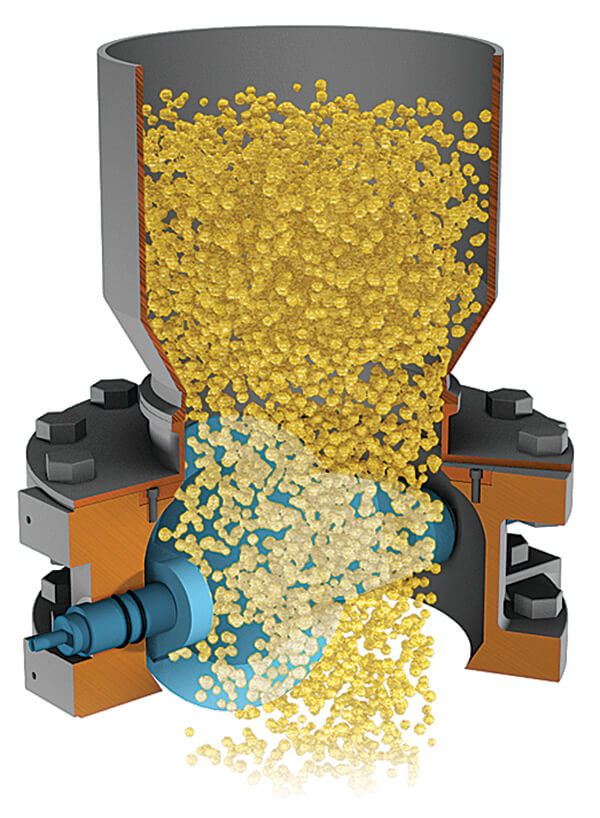

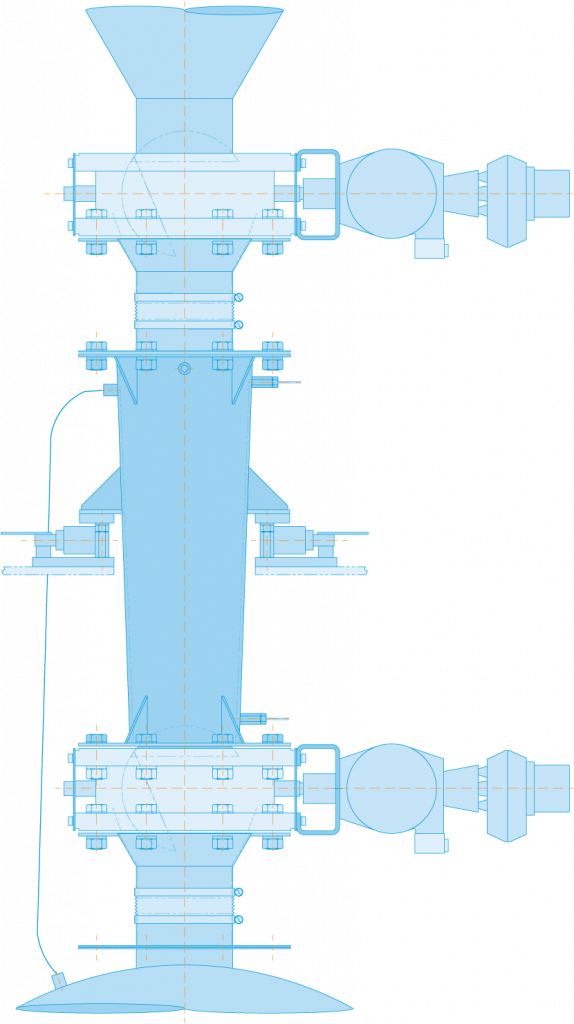

Heavy-Duty Spherical Valves

Since 1984, Roto-Disc®, Inc. has been a trusted manufacturer of valves, airlocks, and diverters for dry and slurry material handling. Our valves are designed and built to order right here in America, individually manufactured to specification based on the requirements of your application.