Diverter valves play a critical role in bulk material handling systems by directing the flow of dry or slurry materials between two or more discharge points.

Whether you’re dealing with powders, granules, pellets, or abrasive materials, choosing the right diverter valve can improve operational efficiency, reduce downtime, and protect equipment from wear.

But what exactly is a diverter valve, and how do you know which type is right for your application? Let’s dive in!

What is a Diverter Valve?

At its core, a diverter valve is a mechanical device designed to change the direction of material flow within a process system.

Commonly used in pneumatic conveying systems and gravity flow applications, diverter valves route bulk materials to various downstream destinations, such as silos, bins, hoppers, or packaging stations.

For example, in a plastics manufacturing facility, a diverter valve might direct plastic pellets from a central conveyor line to one of three hoppers, depending on the batch type or process step. This ensures seamless routing without requiring the system to stop or be reconfigured manually.

Think of them as traffic controllers for your product flow, keeping your system running smoothly while ensuring materials get where they need to go.

What Industries Are Diverter Valves Used In?

Durability and reliability make diverter valves essential for any system requiring clean switching between destinations, especially in industry environments where contamination or leakage cannot be tolerated, including:

- Food processing: Diverter valves are used in baking facilities to route flour from a central silo to multiple mixing lines, ensuring the right blend reaches the appropriate batch without cross-contamination.

- Pharmaceutical manufacturing: In a capsule production plant, diverter valves control the flow of different powders into separate formulation tanks based on the production schedule.

- Chemical plants: Diverters are used to route resins or additives to different reactors, depending on the desired compound being synthesized.

- Plastics and polymers: In pelletizing operations, diverter valves might distribute processed pellets to various packaging stations based on product grade.

- Mining and minerals: Diverter valves handle heavy-duty applications such as directing limestone or fly ash to specific storage silos or transport systems.

Types of Diverter Valves

There’s no one-size-fits-all when it comes to diverter valves. Roto-Disc specializes in two types of diverter valves, each engineered for different performance needs in industrial systems.

Below is an overview of these designs and how they operate.

1. Blade-Type Diverter Valves

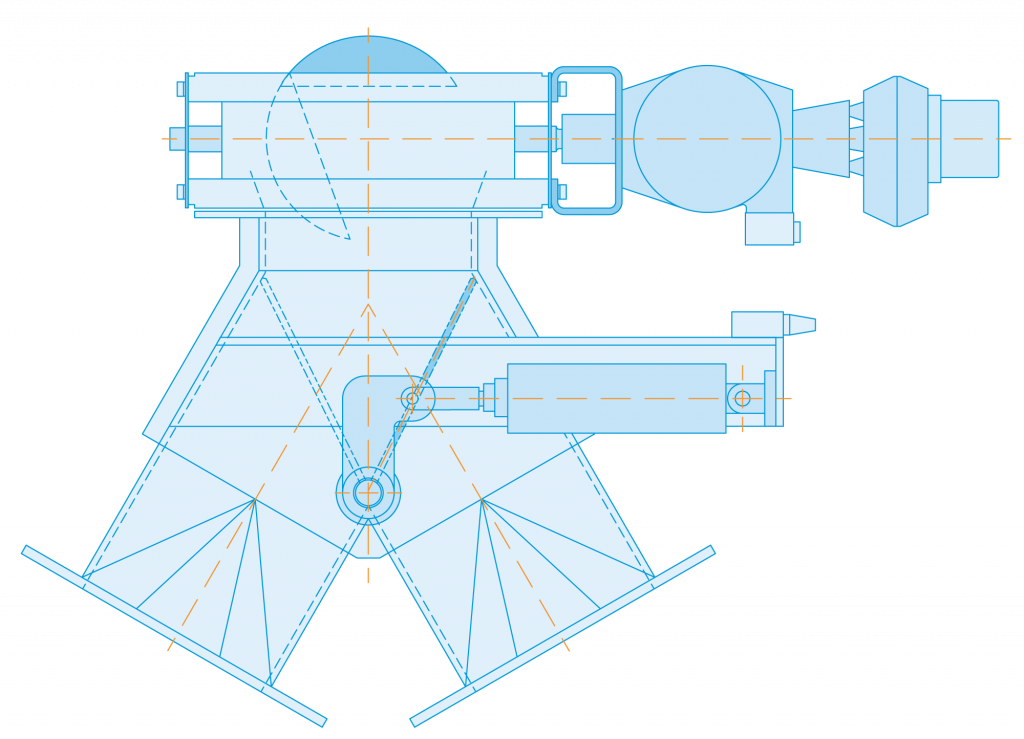

Blade-type diverters, like the Roto-Blade™, use rotating blades to direct the flow of material to a chosen outlet. Known for fast switching and precise control, these heavy-duty valves are ideal when you need minimal material loss and clean transitions between destinations.

2. Inflatable Seal Spherical Diverter Valves

Inflatable seal diverters, such as Roto-Disc’s Roto-Vert-Flate™, use an inflatable bladder to seal off one outlet while allowing material to flow through another.

This ensures a tight seal that reduces cross-contamination and improves flow efficiency, particularly in powder-heavy pneumatic systems.

What Makes Clean Flow Diverters Different?

Clean flow diverters, like the Roto-Blade™ series, are engineered with full-bore openings and streamlined geometry to eliminate dead zones. This makes them easier to clean and less prone to contamination, particularly in sanitary environments like dairy and food processing.

Diverter Valves vs. Blow-Off Valves

Not all valves are created for the same job. While diverter valves control where materials go, blow-off valves serve as pressure-release mechanisms. Knowing the difference can save you from system inefficiencies—or worse, equipment failure.

- Diverter valves are designed to control the direction of material flow. For example, in a baking facility, a diverter might direct flour from a main silo to one of several mixers, allowing for precise routing of ingredients without cross-contamination.

- Blow-off valves, on the other hand, are safety devices. Their purpose is to relieve excess pressure within a pneumatic system. In a conveying line, a blow-off valve might activate to vent built-up air and prevent damage to pipes, filters, or sensitive processing equipment.

How to Choose the Right Diverter Valve

Your system’s efficiency depends on matching the right valve to the job. A poor fit can mean costly downtime or frequent maintenance. Here’s what to consider before selecting a diverter valve:

Material Characteristics

Are you handling abrasive minerals, sticky food products, or fine powders? For abrasive or heavy-duty materials, the ROTO-Disc® Heavy-Duty Spherical Valve offers the durability needed to minimize wear.

For a detailed look at how abrasive materials affect diverter valve performance—and what design features help prevent wear, read “Conquering the Main Wear Factors in Diverter Valves” from Processing Magazine.

Flow Method

Is your system gravity-fed or pneumatic? Pneumatic systems benefit from the ROTO-Vert®-Flate or Roto-Flate® valves, designed for high-speed conveying.

Cycle Frequency

High-cycle applications need designs that minimize wear and reduce maintenance. We recommend the Roto-Blade™ Clean Flow Diverter Valve for reliable performance in frequent switching scenarios.

Cleanability

For sanitary or allergen-sensitive environments, easy cleaning is critical. The ROTO-Clean® Sanitary Spherical Valve is designed with smooth surfaces for quick washdowns.

Space Constraints

Some diverter valves have a larger footprint. The ROTO-Disc® Lighter Weight Spherical Valve offers a more compact solution where space is limited.

Seal Performance

Tight seals prevent contamination and leakage, especially in the food and pharmaceutical industries. The Roto-Flate® Inflatable Seal Spherical Valve provides exceptional sealing performance for critical applications.

When to Consider a Spherical Disc Valve

If your material handling system requires clean, fast, and reliable operation with minimal intervention, a spherical disc valve may be the best option.

Spherical disc valves are ideal for systems that require frequent switching, clean-in-place capabilities, and long-term durability.

Their self-cleaning design and minimal maintenance make them a smart choice for abrasive, sanitary, or high-cycle applications, especially in pneumatic conveying environments.

Contact Roto-Disc for Your Diverter Valve Needs

Diverter valves may be small, but they can have a major impact on your material handling system. Whether you’re aiming to improve uptime, prevent contamination, or increase equipment life, Roto-Disc offers high-performance diverters engineered for the job!

Our team works closely with engineers, plant managers, and system designers to ensure each valve is optimized for your specific application.

We’ll help you review your current system, recommend the right solution, and even calculate your potential ROI. Contact us today to get started!