Roto-Disc, Inc. has airlock/double-dump valves able to feed and measure product into and/or out of pressure or vacuum environments in four different modes.

Through the development of the Roto-Disc Cycle Timer (RDCC™) and enhancements to its accumulator chambers, customers have access to volumetric and gravimetric measuring capability, in addition to traditional temporal and manual control.

Your teams can switch between any of these modes almost instantaneously and then return to operation just as quickly, providing unparalleled measurement flexibility for processing dry or slurry material.

Gravimetric Solutions

The new feeding solutions are accomplished with load-cell mounts and/or level sensor ports, both of which are located on the chamber according to the application requirements. Gravimetric solutions are provided with flexible connections on the assembly for accurate weight measurement. This is a revolutionary processing solution that can take the place of other feeding devices and make your process more efficient, as well as avoiding the pitfalls of traditional feeding valve solutions.

Materials Processing Into and Out of Differential Pressure Environments

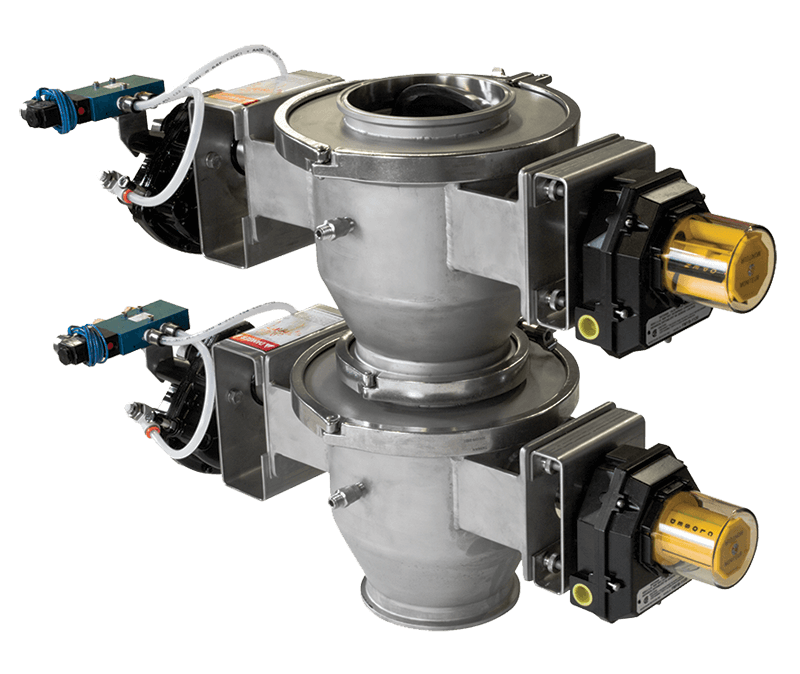

This Roto-Disc® valve design takes double-dump valves to the next level. Our double-dump assemblies can be used to process material into/out of differential pressure environments by timing, weight or volume. This is a revolutionary processing solution that can take the place of other feeding devices and make your process more efficient!

Customizable Solutions With Airlock/Double-Dump Industrial Valve Assemblies

Intermediate accumulator chambers are designed for ledge-free flow of material from valve to valve. Cycle-timing and pressure equalization couplings are available for turn-key feeding solutions.

Accumulator chambers can be sized to suit your processing needs. Our team can custom-make feed hoppers and funnels per customer requirements. Custom intermediate accumulator chambers can meet a specific volume and/or take-out space requirements.

Problems Solved by the Roto-Disc Airlock/Double-Dump Valve Assembly

These are the perfect replacement for leaky rotary-vane valves or other, flimsy double-dump valves. Rotary valves have a gap between the blade ends and the housing that allow leakage. The constant scraping of material between the blade and housing causes even hardened surfaces to wear-out. Pressure or vacuum that passes through the rotary valve can hinder product flow, reduce the efficiency of the system, and lead to breakage and downtime.

Variants of the Airlock/Double-Dump Industrial Valves

There are two variants of the Roto-Disc airlock/double-dump industrial valves to meet the needs of your company’s processes.

Roto-Flate® Airlock/Double-Dump Assembly

Whereas the original airlock/double-dump assembly is for dry materials and slurry, Roto-Flate® valves work for liquids, gases, and dry materias. Roto-Flate® valves feature a bubble-tight sealing system that is ideal for high pressure and vacuum environments. The positive seal prevents leakage of liquids, gasses or dry material into or out of the valve. Bubble-tight sealing means your process runs more efficiently because compressors or vacuum pumps won’t be overloaded.

Roto-Clean® Airlock/Double-Dump Assembly

For food manufacturing or pharmaceuticals, you company needs the Roto-Clean® valve that’s easy to disassemble and clean. The Roto-Clean® valve wipes itself clean with each cycle while slicing through sticky, gummy material build-up. All product contact surfaces are of FDA-compliant materials.

This valve is ideal for when your team needs to clean valves frequently. The action of the valve keeps product moving, reducing your downtime and cleaning time compared to older, out-of-date processing equipment.

Invest in Roto-Disc® Industrial Valves

Roto-Disc, Inc., is a world leader in custom valves that make your processes more efficient while reducing labor costs and downtime. Contact Roto-Disc today to learn more about how we can help your company improve its processes and achieve optimal results.