Choosing the Right Diverter Valve: Clean Flow vs. Traditional Designs

When you’re running a bulk material handling system, every component plays a role in your bottom line. However, when it comes to system flow, contamination

When you’re running a bulk material handling system, every component plays a role in your bottom line. However, when it comes to system flow, contamination

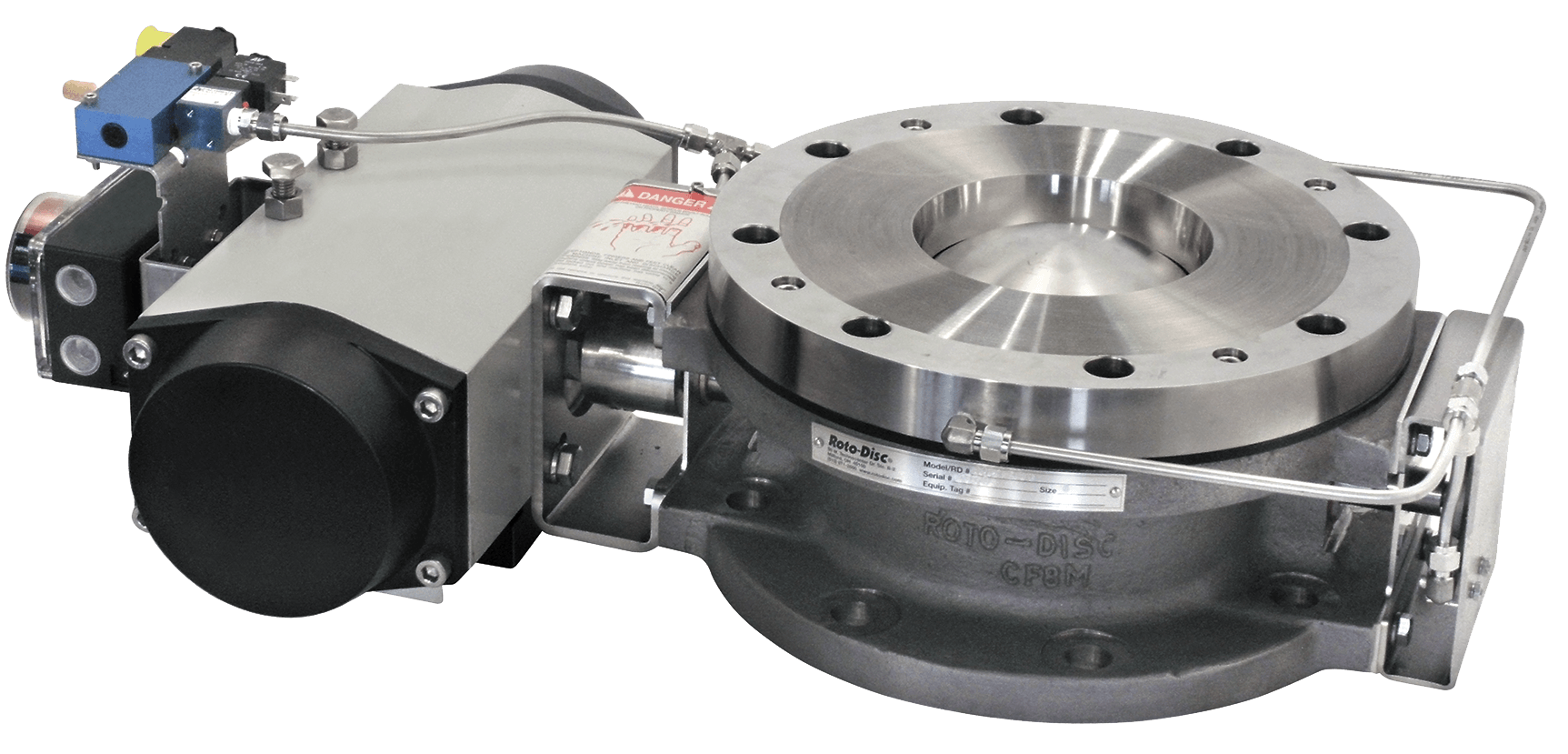

Do your industrial valves work as efficiently as possible? If not, perhaps it’s time for an upgrade. Roto-Disc, Inc. specializes in custom-made industrial valves and

Roto-Disc, Inc. continues to innovate our industrial valve selections for every industry we serve, including ones that require high-pressure and vacuum environments. Our complete guide

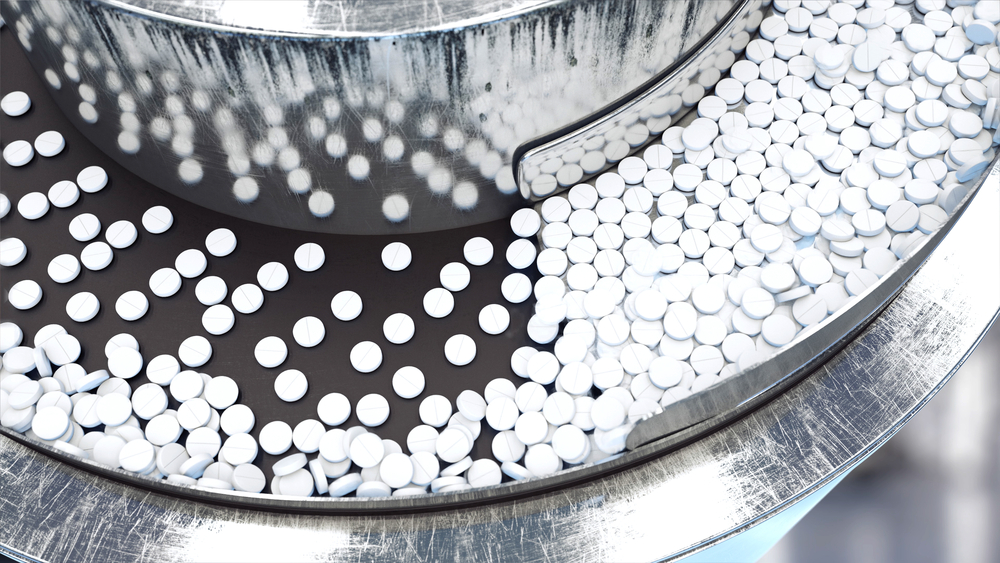

Roto-Disc, Inc. remains focused on continuous improvement and product innovation for all industries we serve, including those industries where purity is paramount. Keep reading to

Roto-Disc, Inc. remains focused on continuous improvement and product innovation. Your industrial processes might benefit from a lighter-weight spherical valve versus a heavy-duty spherical valve.

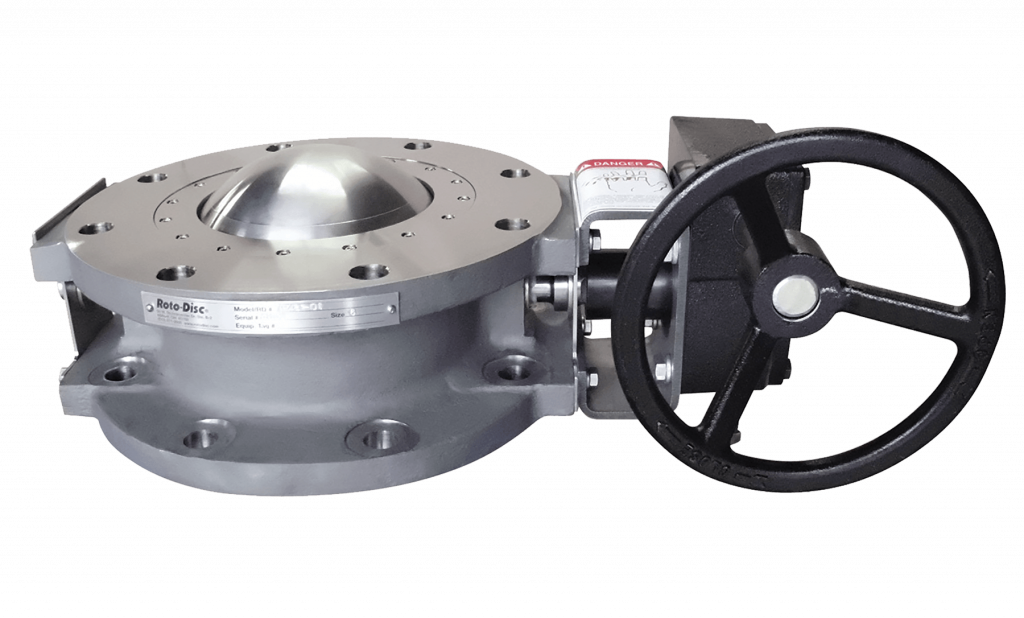

The team at Roto-Disc has continued to improve our products over the years. One of those innovations is the Roto-Disc® heavy-duty spherical valve, which can

Roto-Disc quarter-turn valves resist seat wear better than most other valve styles. The dome of the Roto-Disc valve wipes against the seat, cleaning itself as

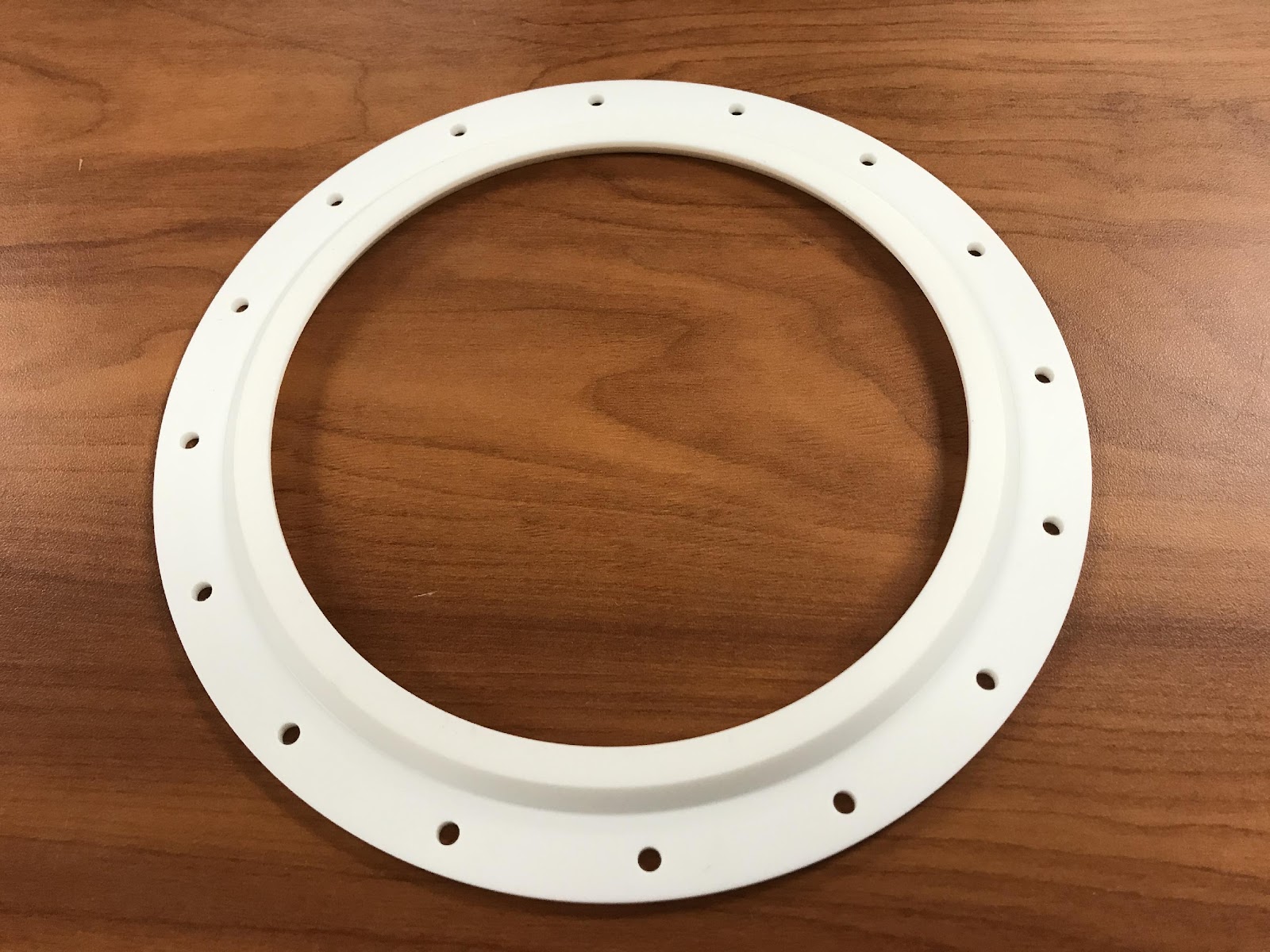

Roto-Disc®, Inc’s patented Roto-Clean® Sanitary, spherical valve comes in several sizes, depending on your equipment’s requirements. This gives your team several advantages over more traditional

Roto-Disc® Inc’s inflatable seal mechanical interlock system for the Roto-Flate® valve enhances its reliability and causes it to fail closed and inflated in the case

Roto-Disc specializes in state-of-the-art industrial valves for a wide range of applications, from liquids handling to powders, pellets, granules, and chips. Our spherical valves help