Choosing the Right Diverter Valve: Clean Flow vs. Traditional Designs

When you’re running a bulk material handling system, every component plays a role in your bottom line. However, when it comes to system flow, contamination

When you’re running a bulk material handling system, every component plays a role in your bottom line. However, when it comes to system flow, contamination

In bulk material handling, precision and efficiency are non-negotiable. Whether you’re moving fine pharmaceutical powders, dense minerals, or food-grade ingredients, system performance hinges on the

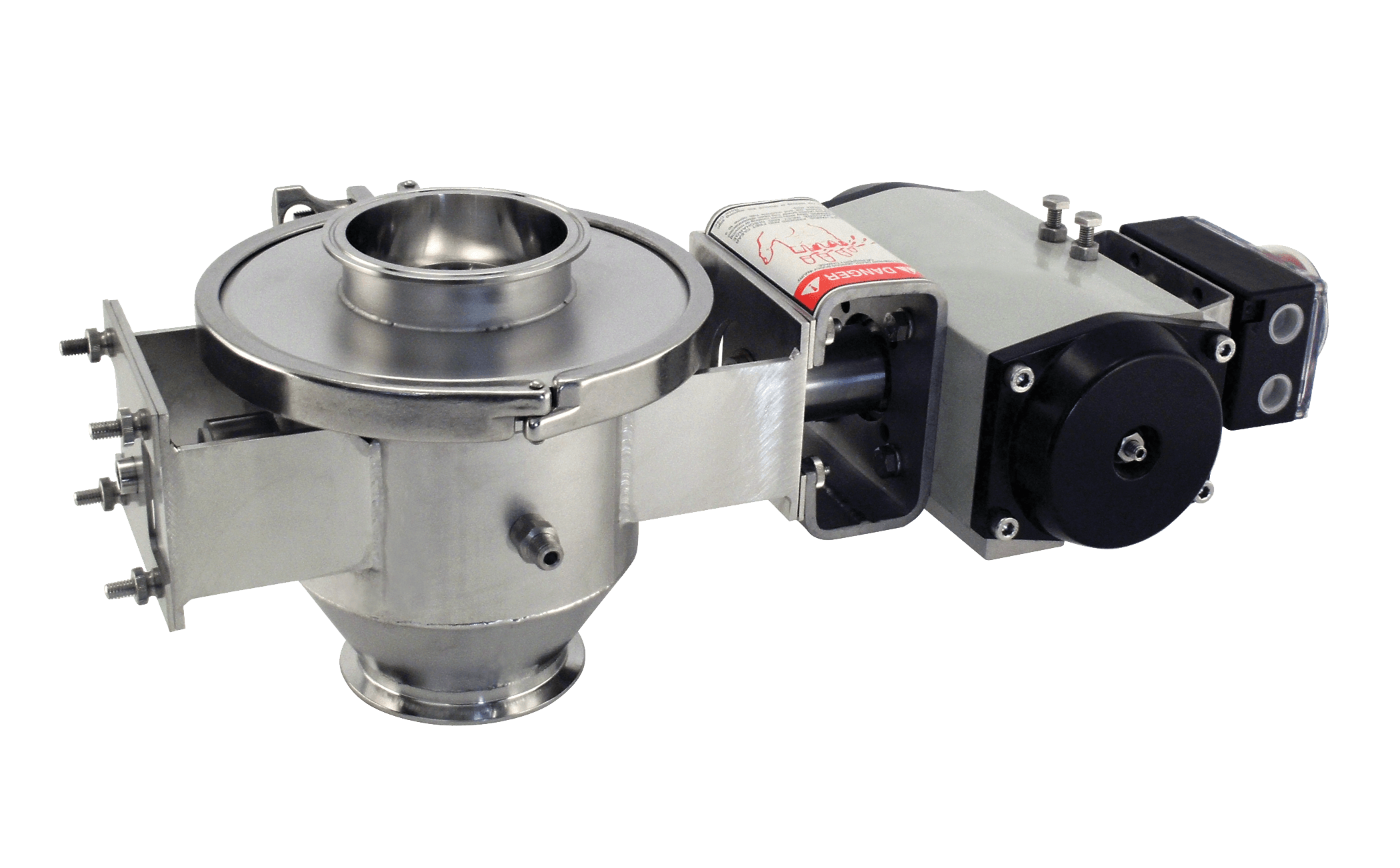

Diverter valves play a critical role in bulk material handling systems by directing the flow of dry or slurry materials between two or more discharge

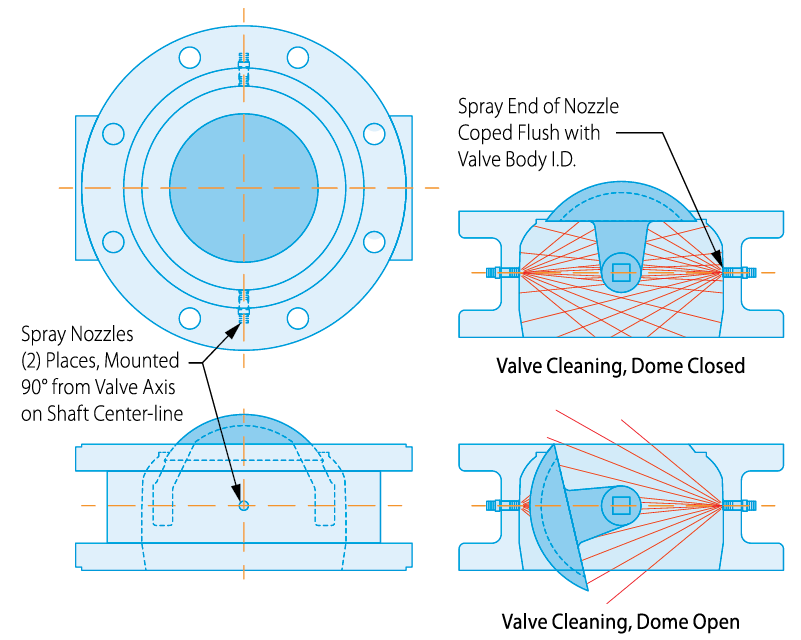

Regular maintenance and servicing of industrial valves ensure their longevity. We’ll share the best practices for maintaining Roto-Disc® valves, designed to help you maximize the

Valve seats must fit within tolerances to work properly. But for industrial processes, valve seats must also withstand high temperatures, high pressures, and many classes

You’ve seen this problem before. As your dry solids move from one area of your production line to another, your transitions valve develops plugs over

Roto-Disc serves several industries with custom-built industrial valves. We’re going to look at these industries and the materials our valves can handle. Industrial Valves for

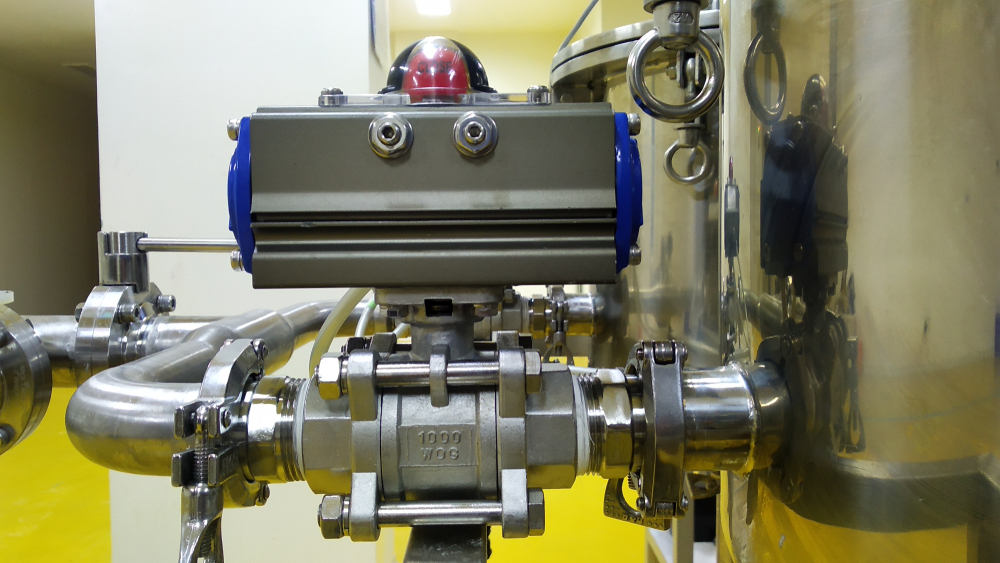

Liquid handling valves represent a necessary component for many manufacturing processes. They offer precise ways to control fluid distribution within your industrial processes, whether you’re

What Is Pneumatic Conveying? Pneumatic conveying involves transporting dry bulk materials using pressurized gas. Pneumatic conveying systems transport bulk materials like grains, pellets and powders

If you are contemplating purchasing a general valve for your system versus a quality custom-made unit, read today’s blog about the benefits of specialty-made products