When you’re moving dry bulk materials, from fine pharmaceutical powders to high-temperature mineral mixes, airlock valves can be the difference between a clean, efficient operation and a cycle of leaks, clogs, and downtime. The right design preserves pressure or vacuum, meters material reliably, and protects product quality. The wrong choice quietly drains performance and budget.

This guide provides engineers, plant managers, and procurement teams with a clear and practical framework for selecting valves in bulk material handling systems.

With a special focus on airlock/double-dump valves versus rotary designs, it breaks down the differences that matter most—durability, sealing performance, cleanability, and cost of ownership.

By the end, you’ll have a solid understanding of how airlock valves function, where each design excels or falls short, and how Roto-Disc’s proven solutions can simplify your decision-making process and improve long-term system performance.

What Is an Airlock Valve?

At a high level, an airlock valve moves material from one pressure zone to another without losing pressure or vacuum.

In bulk solids processing, airlocks are commonly located under cyclones, baghouses, hoppers, and feed devices, controlling discharge while maintaining system integrity.

The best airlocks:

- Protect upstream and downstream pressure balance

- Minimize blow-by and product loss

- Meter or batch material reliably

- Reduce dusting and contamination risk

The two dominant airlock valve types you’ll encounter are:

- Rotary Airlock Valves: A rotating rotor (with pockets) meters material continuously through a housing while providing a pressure “seal.”

- Airlock/Double-Dump Valves: Two valves operate in sequence (fill → isolate → dump → reset) to transfer material in discrete batches while keeping pressure tight, without a rotating rotor.

If you’re dealing with persistent leaks, seal wear, or clogging in demanding conditions, there’s a good chance you’re evaluating your options. You’re in the right place!

Core Use Cases (and Why They Matter)

Airlock valves are used wherever bulk material must move across a pressure differential—under cyclones and baghouses, beneath hoppers, and at feed transfer points—so discharge control doesn’t compromise system pressure.

- Pneumatic conveying (feeding into/receiving from a pressurized line)

- Dust collection (discharging from baghouses/cyclones without losing vacuum)

- Batch dosing (accurate adds to mixers or reactors)

- High-temperature or abrasive service (foundries, minerals, glass batch)

Because operating conditions vary significantly, the choice of design (rotary vs. double-dump) directly affects uptime, wear life, cleaning frequency, energy consumption, and product quality.

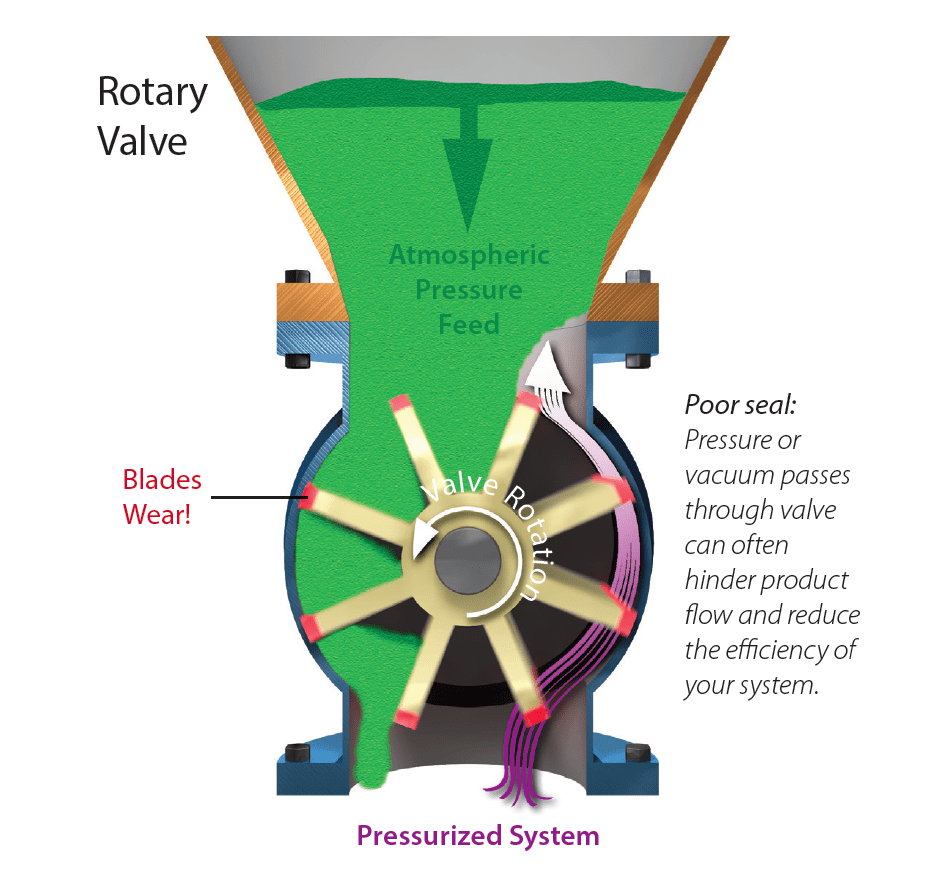

Rotary Airlock Valves: Where They Excel—and Where They Struggle

Rotary airlock valves are a staple in bulk material handling, trusted for their ability to meter product while maintaining pressure balance. But like any workhorse, they come with trade-offs.

How they work: A rotor turns within a precisely machined housing. Material fills each pocket, passes through, and discharges (continuously) while the geometry limits air passage.

Rotary Airlock Strengths

- Continuous flow and good metering precision for fine, uniform powders

- Compact designs that integrate easily under cyclones or hoppers

- Wide availability in various sizes and materials

Rotary Airlock Challenges

- Seal wear and leakage as clearances open over time

- Rotor scraping/metal-on-metal contact in abrasive or oversized solids

- Clogging with sticky, damp, or irregular material

- More frequent maintenance (bearings, seals, rotor edges)

For a deeper engineering perspective on spec trade-offs, see Process Magazines’ overview of rotary airlock valve design factors.

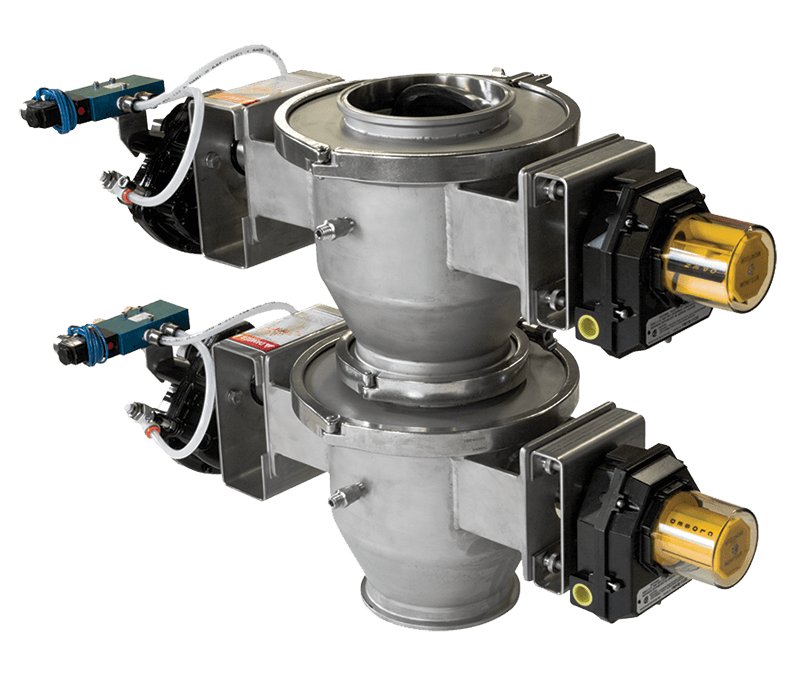

Airlock/Double-Dump Valves: Tight Sealing, Tough Conditions

When the job demands rugged reliability, airlock/double-dump valves step in.

Instead of relying on a constantly spinning rotor, they utilize two sealing stages to control material flow, delivering exceptional containment and durability in abrasive, high-temperature, or pressure-sensitive environments.

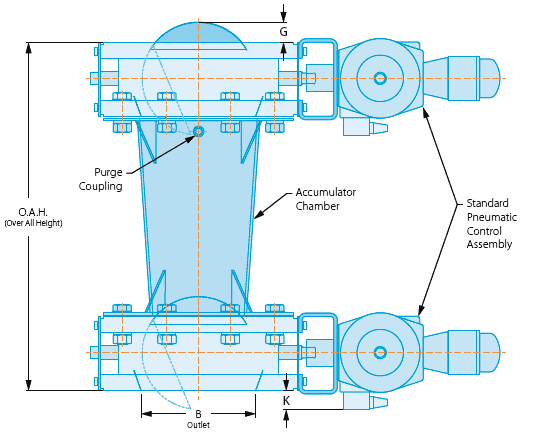

How they work: Two valves open/close in sequence to move material in discrete batches without exposing the system to open flow paths. The typical cycle is:

- Fill (top valve open, bottom closed)

- Isolate (top closed, material is contained)

- Dump (bottom open, material discharges)

- Reset (bottom closed, ready to repeat)

Because they don’t depend on a rotating rotor, airlock/double-dump valves avoid many of the wear issues rotary designs struggle with in demanding environments.

Airlock/Double-Dump Strengths

- Excellent pressure integrity in harsh conditions

- Lower wear with abrasive, hot, or irregular material (no rotor scraping)

- Predictable cycles for batching or protected discharge

- Ledge-free interior options to reduce buildup

Rotary Airlock vs Double-Dump Valves:

When engineers are weighing rotary airlock vs double-dump valve designs, the differences can be subtle at first glance—but they matter.

Each design brings its own strengths and trade-offs depending on the material, pressure, and operating environment.

Choose a Rotary Airlock When…

- You need continuous discharge and metering precision

- Material is fine, dry, uniform (e.g., flour, starch, fine polymer powders)

- Space is tight, and simplicity is a must

- Sanitary polishing and specific rotor finishes are available and appropriate for your process

Choose an Airlock/Double-Dump When…

- You handle abrasive, hot, or irregular solids (foundry, mineral, glass batch)

- Pressure tightness is critical (minimize blow-by)

- Sticky or damp powders risk jamming a rotor

- You want to reduce wear and extend maintenance intervals

To help you evaluate the best fit for your process, here’s a side-by-side comparison highlighting performance, maintenance, energy use, and typical applications:

| Feature | Rotary Airlock Valve | Double-Dump Valve |

|---|---|---|

| Best For | Free-flowing powders, grains, fine materials | Hot, abrasive, or irregular materials |

| Seal Performance | Moderate — seals wear over time | Excellent— tight, pressure-resistant sealing |

| Maintenance Needs | High— rotors and seals require frequent attention | Low— fewer moving parts, less wear |

| Energy Use | Higher due to rotor drag and leakage | Lower— efficient design minimizes blow-by |

| Contamination Risk | Moderate to high with sticky/abrasive materials | Low—designed to prevent leakage and contamination |

| Typical Applications | Powder metering, pneumatic conveying | High-temp/abrasive solids, chemical/pharma, explosion containment |

Takeaway: Rotary airlocks remain a staple for powders and continuous metering. For abrasive, hot, or irregular solids, or where leakage tolerance is near zero, airlock/double-dump designs generally deliver better sealing and lifecycle economics.

Valve Selection for Bulk Material Handling: A Step-by-Step Checklist

Choosing between rotary airlock valves and airlock/double-dump valves doesn’t have to be guesswork. Use this four-step checklist to match your application to the right design:

1. Understand Your Material

- Fine, free-flowing powders → Rotary airlock (continuous metering)

- Abrasive or irregular solids → Double-dump (reduced wear; no rotor scraping)

- Sticky/damp powders → Double-dump (avoids rotor jams/seal failures)

2. Evaluate Your Process Environment

- High pressure/high temperature → Double-dump (tighter seal; longer life)

- Moderate pressure with steady flow → Rotary Airlock (simpler, often lower cost)

- Strict dust/emissions limits → Double-dump (superior containment)

3. Define Performance Priorities

- Continuous discharge & precise metering → Rotary airlock

- Batch isolation & minimal leakage → Double-dump

- Sanitation/allergen control → Double-dump with ledge-free internals

4. Plan for Lifecycle & Compliance

- OK with frequent maintenance/simple spares → Rotary airlock

- Prefer fewer rebuilds/longer uptime → Double-dump

- Explosion containment/inert handling → Double-dump

Installation & Maintenance: Key Considerations

Even the best-designed airlock needs proper installation and care:

- Keep flanges true and concentric

- Select seals matched to temperature, chemistry, and abrasion

- Plan for quick inspections and stocked wear parts

For double-dumps, verify cycle timing, interlocks, and pressure equalization; for rotaries, monitor rotor clearances, motor load, and bearing temperatures. Good venting and dust collection reduce fugitive emissions and premature wear.

Frequently Asked Questions

Rotary valves continuously discharge fine, uniform powders using a rotating rotor. Double-dump valves, conversely, transfer material in discrete batches, following a fill/isolate/dump/reset cycle. They are particularly well-suited for abrasive, hot, or irregular materials where sealing and wear are critical.

Choose a double-dump when you need tight sealing, reduced wear without a rotor, or when material tends to jam or abrade rotary internals (e.g., glass batch, minerals, foundry solids).

Yes. They’re often used upstream of conveying lines where pressure integrity matters, and downstream where you want controlled, low-leakage discharge.

Start with material behavior (size, abrasion, moisture), process conditions (temperature/pressure), and performance priorities (metering vs isolation). Then factor in cleanability, access, and lifecycle maintenance.

Don’t Let the Wrong Airlock Slow You Down

An underperforming airlock doesn’t just wear parts—it wears down your entire process. If you’re dealing with seal wear, clogs, or leaks, compare options with a clear, engineering-first lens.

Roto-Disc can review your setup and provide a side-by-side comparison of rotary and airlock/double-dump valves, based on your material and operating conditions. Contact us today to get started!