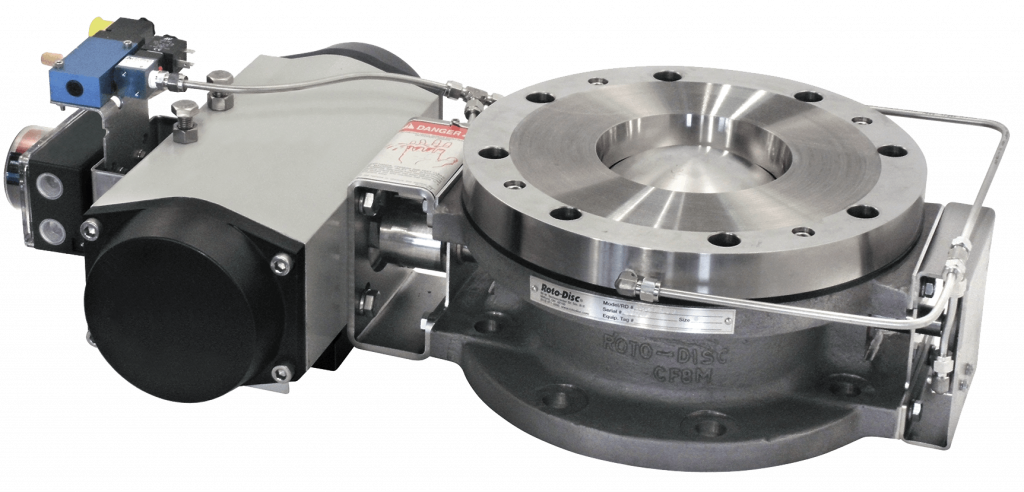

Roto-Disc, Inc., is a world leader in industrial valves for dry material handling processes. One of our top models is the Roto-Flate inflatable seal spherical valve. It’s ideal for high-pressure and vacuum environments.

Discover four main benefits of inflatable seal spherical valves for your equipment and production lines.

1. Bubble-Tight Sealing

Bubble-tight sealing means no leakage of material or passage of gas pressure. This is ideal for environments that are sensitive to air/oxygen ingress such as vacuum drying or reaction processing.

The Roto-Flate also seals dynamically, which means it can maintain a bubble-tight seal against pressure or vacuum. This is ideal for processes that shift from pressure to vacuum during the same cycle. This is a requirement of many vacuum drying/vacuum reactor processes and one that presents a problem for typical discharge valves. The Roto-Flate is an ideal choice for such applications!

Related Post: Roto-Flate® Valve Now Designed To Close And Inflate In All Failure Modes

2. More Efficient Pneumatic Conveying

Many valves used in pneumatic conveying, such as knife-gate or slide-gate valves don’t provide tight seals, even when they are new from the factory. This means that vacuum pumps or air compressors have to work to overcome the constant leakage of air or process gasses. Because the Roto-Flate provides a bubble-tight seal, vacuum pumps and air compressors aren’t overloaded and so they work more efficiently.

3. Unobstructed Flow of Product

Butterfly valves are frequently used in dry material handling processes and are favored for their low cost. Unfortunately, they have a vane directly in the middle of the product stream which significantly cuts throughput and often causes product bridging. The dome of the Roto-Flate valve rotates completely out of the way of the inlet opening, providing a fully-open bore that won’t obstruct product flow. This means that smaller Roto-Flate valves can be used to accomplish the same job which reduces the price differential.

4. Minimized Wear

Seal wear is a constant worry in demanding valve applications. Most times, wear is a function of the process media abraiding the sealing surfaces as it flows past. But the sealing surfaces of the Roto-Flate are hidden from product flow when the valve is fully open.

As such, even abrasive, materials will not wear the seal as with standard valve assemblies.

Related Post: Top 4 Markets for Industrial Spherical Valves

Roto-Disc, Inc., Helps Many Companies Succeed With Our Inflatable Seal Spherical Valves

Roto-Disc can custom-make industrial valve assemblies for a wide range of industries and applications. Our inflatable seal spherical valves will help improve your industrial processes if you require a vacuum or high-pressure environment to move products through your line.

Contact Roto-Disc today to learn more about how we can help your company improve its processes and achieve optimal results.