Glass is everywhere—from the phone screens you rely on every day to the glasses you drink from, and even the insulation inside your walls.

The journey from a glass batch of powdery raw materials to a finished product is anything but simple. Each step—mixing, melting, forming, and annealing—relies on steady, obstruction-free material flow. That’s where Roto-Disc® valves come in.

In this blog post, we’ll connect the dots between the composition of glass batches and the finished glass you use every day, as well as how our spherical valves and Airlock/Double-Dump Valve Assemblies keep abrasive, high-temperature mixtures moving safely and efficiently on the plant floor.

What Is a Glass Batch?

A glass batch is a carefully measured mixture of raw ingredients that are melted to form glass. The materials used to create a glass batch include:

Silica sand

The main glass-forming mineral

Soda ash

Lowers the sand’s melting temperature

Limestone

Adds strength and chemical durability

Plants mill and blend these powders until they form a uniform mix called the batch. Most producers also incorporate cullet—clean, crushed recycled glass, which melts faster than raw sand and reduces furnace temperatures, saving both energy and emissions.

The combined batch and cullet are fed into a furnace and heated to roughly 1,500 °C (2,730 °F). At that point, the mixture fuses into a glowing, honey-like molten glass.

Kept at high heat, this molten mass stays fluid long enough to be shaped—whether into bottles, window sheets, or fine fibers—before controlled cooling locks the material into its final solid form.

Pro tip: Plants that recycle cullet save up to 3 % energy for every 10 % cullet added, according to the Glass Manufacturing Industry Council (GMIC).

The Four Stages of Glass Manufacturing

Batching & Mixing

Raw materials are weighed, blended, and conveyed to storage silos.

Melting

Furnaces at 1,500 °C (2,732 °F) liquefy the batch into a homogeneous molten glass.

Forming

Gob feeders, float baths, or pressing molds shape glass into bottles, sheets, or fibers.

Annealing & Finishing

Controlled cooling relieves internal stress and adds coatings, cut edges, or decorations.

Each stage of glass manufacturing has its own flow-control challenges. When a valve sticks or leaks, the line doesn’t just slow down—it can shut down a multimillion-dollar furnace. We will dive deeper into this below.

Why Glass Batch Is Tough on Conventional Valves

Unless a valve is purpose-built, the combination of sharp silica, hygroscopic soda ash, and high furnace temperatures will shred seals and stall production.

That’s why many glass plants upgrade to Roto-Disc® spherical or double-dump valves—they remove the ledges, shaft seals, and tight clearances that traditional slide gates and rotary airlocks can’t protect.

Here’s what standard valves are up against:

- Abrasive particles score housings and gaskets, widening clearances until leaks appear.

- Hygroscopic soda ash cakes on warm metal, creating a buildup that chokes flow.

- High temperatures (often 200°F or more in pneumatic lines) warp elastomer seals.

- Fine dust escapes through clearances and shaft seals, contaminating bearings and instruments.

Our valves eliminate those weak points with a polished spherical plug that wipes clean each cycle and seats bubble-tight—no shaft seals, no dead zones, no ledges for powder to hang up.

Roto-Disc® Spherical Valves: Designed for Glass Batch

Instead of flat plates or rotating blades, Roto-Disc® valves use a polished stainless-steel sphere that seats bubble-tight against a matching seat. The benefits of glass manufacturing are immediate:

No Ledges, No Build-Up

Powder slides off the sphere, keeping the flow path clear.

Bubble-Tight Seal

Stops false air and maintains stable furnace pressure.

Minimal Wear Points

Only two hardened surfaces touch, reducing downtime.

High-Temp Options

Inconel seats and ceramic linings withstand streams exceeding 1,000°F.

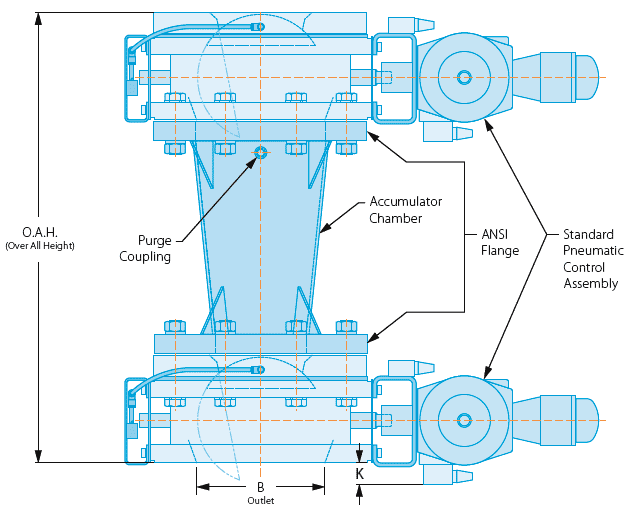

Going a Step Further: Airlock/Double-Dump Valves

When you must meter batch material from a high-pressure silo into a low-pressure conveyor—or vice versa—the Airlock/Double-Dump Valve Assembly shines.

Two Roto-Disc® spheres work in sequence:

Fill

Upper valve opens; lower stays shut.

Isolate

Upper closes, trapping a measured pocket.

Dump

Lower opens; pocket drops downstream.

Reset

Lower closes; chamber re-pressurizes.

Because only one valve is open at any time, pressure integrity is never compromised. Plants report smoother furnace draft control and 20–40 % blower energy savings after converting leaky rotary airlocks.

Frequently Asked Questions

Q: Will a spherical valve handle molten glass?

A: Roto-Disc® valves meter hot batch and cullet just before they are melted. Once the material is fully molten, refractory troughs or float baths take over the process.

Q: How often do seats require resurfacing?

A: In abrasive glass batch service, many customers regrind seats annually during scheduled furnace rebuilds, eliminating the need for full valve replacement.

Q: Can I retrofit without cutting the pipe?

A: Yes. Drop-in flange adaptors match your existing bolt pattern, allowing for a single-shift installation.

Ready to Upgrade Your Glass Batch Flow?

Our patented spherical valves and double-dump assemblies are built for harsh conditions and engineered to drop into your existing system with minimal retrofitting. When all else fails, we’ll review your current setup, provide recommendations, and show you the ROI using your plant’s actual numbers. Contact us today to get started!