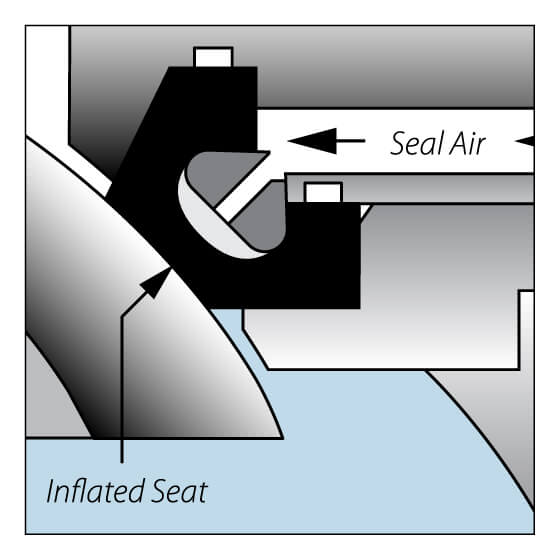

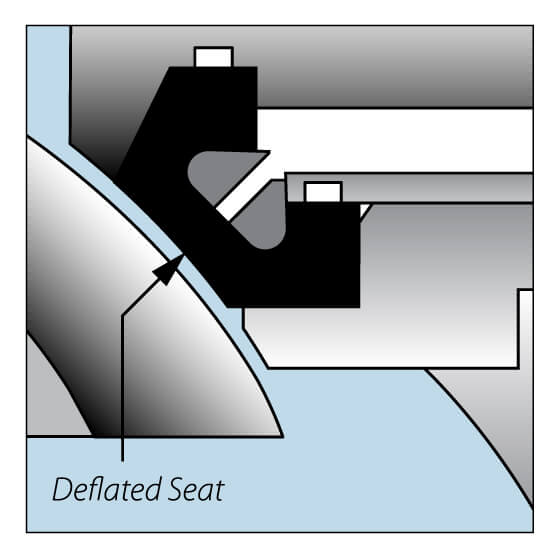

Compressed air enters the inflatable seal assembly and inflates the seal against the dome

Compressed air is released causing the seal to relax and allowing the dome to rotate.

Roto-Flate® valves feature a bubble-tight sealing system that is ideal for high pressure and vacuum environments. The positive seal prevents leakage of liquids, gasses or dry material into or out of the valve. Bubble-tight sealing means your process runs more efficiently because compressors or vacuum pumps won’t be overloaded.

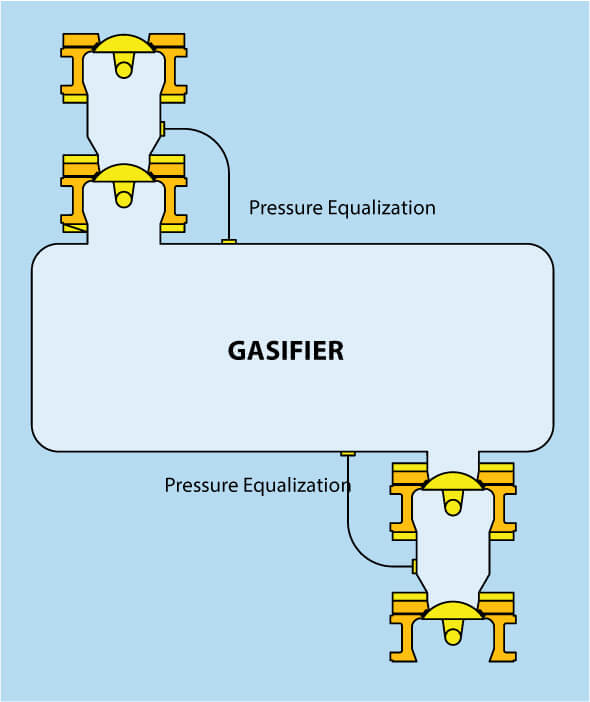

Lock-Hopper Valves: Two Roto-Flate® valves are placed in series and are opened and closed independently so pressure or vacuum is contained above or below the assembly.

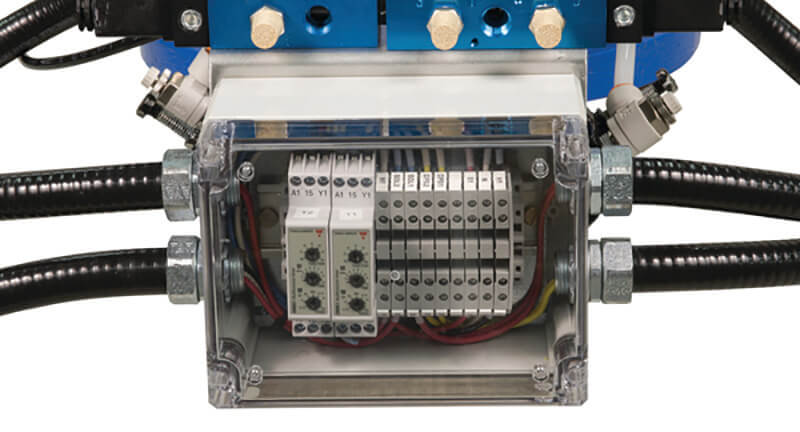

The Automated Sequence Controller (ASC) allows the Roto-Flate® to be controlled with just one signal to open and one to close. This unique device, developed exclusively by Roto-Disc®, Inc. makes controlling the Roto-Flate® as easy as any quarter-turn valve, and still provide the high performance of a two-stage sealing system.

Stainless Steel (304, 316, Duplex), Hastelloy-C, Inconel, Monel, Carbon Steel (4140, WCB, A36), Other alloys upon request

EPDM, Heat-Stable Silicon, Viton®- A/B/GF, Viton Extreme ETP, Buna-Nitrile, Neoprene. Some materials available in white.

Electroless Nickel, Stellite, Hard Chrome, Thin-Dense Chrome, Tungsten Carbide, Teflon®/PFA, Others