Stainless Steel (304, 316, Duplex), Hastelloy-C, Inconel, Monel, Carbon Steel (4140, WCB, A36), Other alloys upon request

Reinforced PTFE (glass fiber, 316SS fiber, carbon fiber), PEEK, Ertalyte, UHMW, Other engineered plastics

Stainless Steel (304, 316, Duplex), AR400 Abrasion Resistant Steel, Hastelloy-C, Inconel, Monel, Other alloys upon request

Electroless Nickel, Stellite, Hard Chrome, Thin-Dense Chrome, Tungsten Carbide, Teflon®/PFA, Others

‡ Pressure and temperature limits of an individual valve depend on a variety of application conditions and materials of construction of the valve

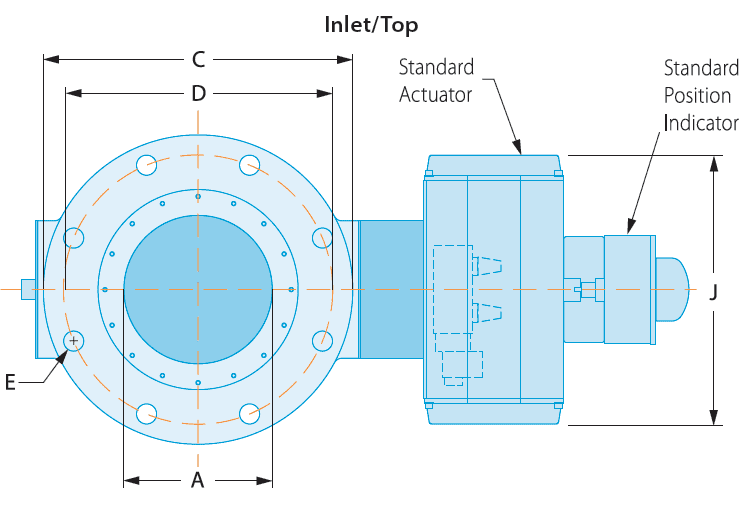

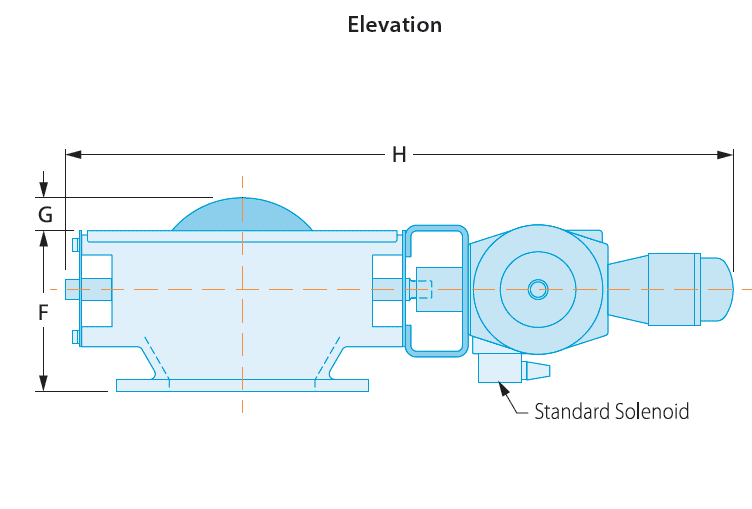

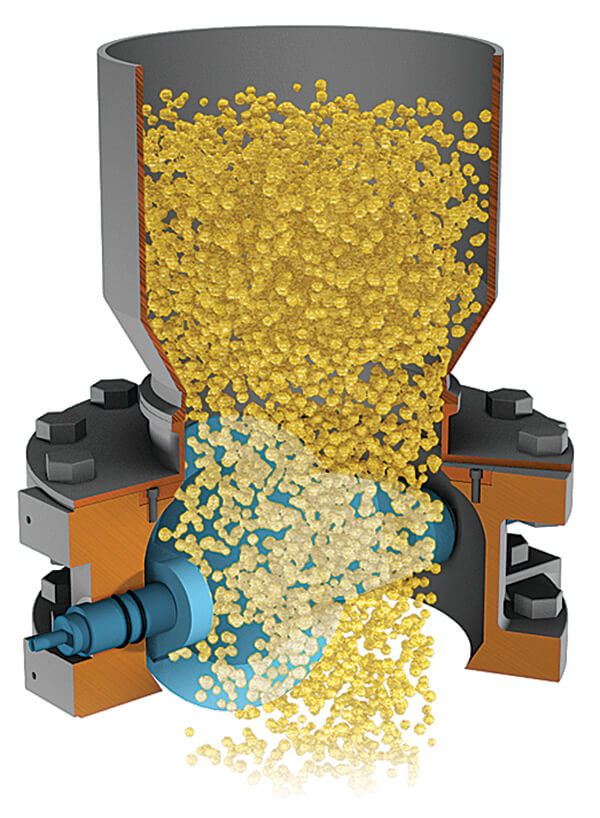

Material falls unobstructed through the inlet opening. Nothing is in the flow stream to cause product bridging, so you get the full flow capacity of the valve. Notice that the sealing surfaces are protected from direct contact with material.

As the valve begins to rotate closed, the dome wipes against the seat, cutting off the flow of product and pushing material above or below the valve instead of wedging it between the dome and seat. The design naturally resists abrasive wear and there are no pinch points or places for material to hang-up.

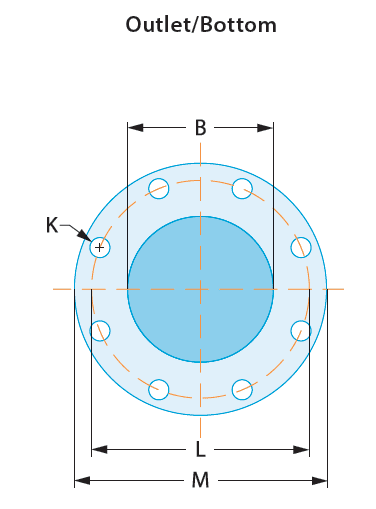

Closure is clean and the valve is fully seated. The dome and seat form a positive seal that eliminates leakage across the seat. Double O-rings prevent leakage through the stems.