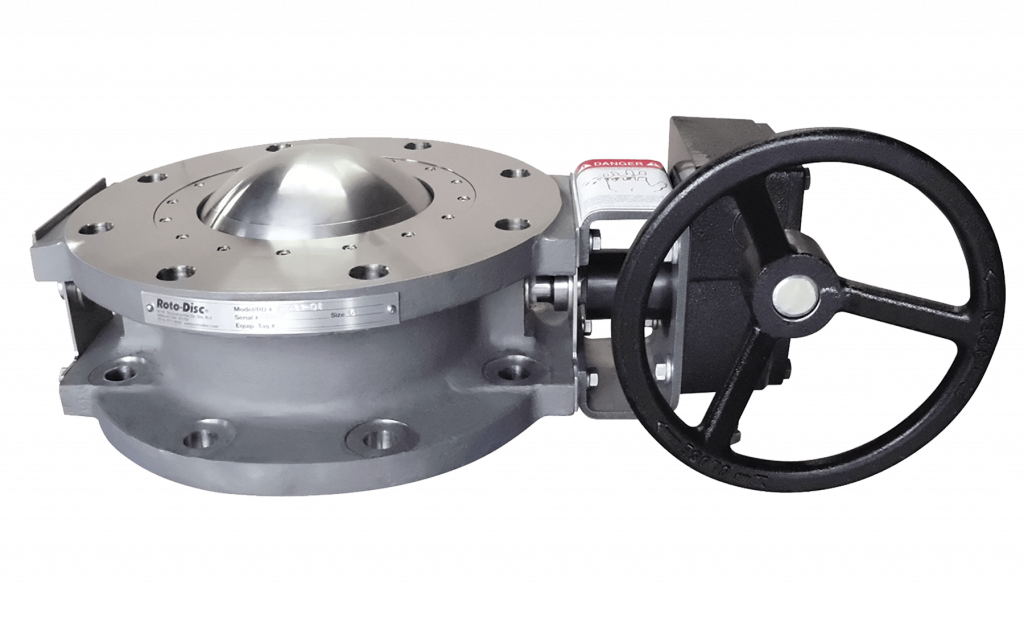

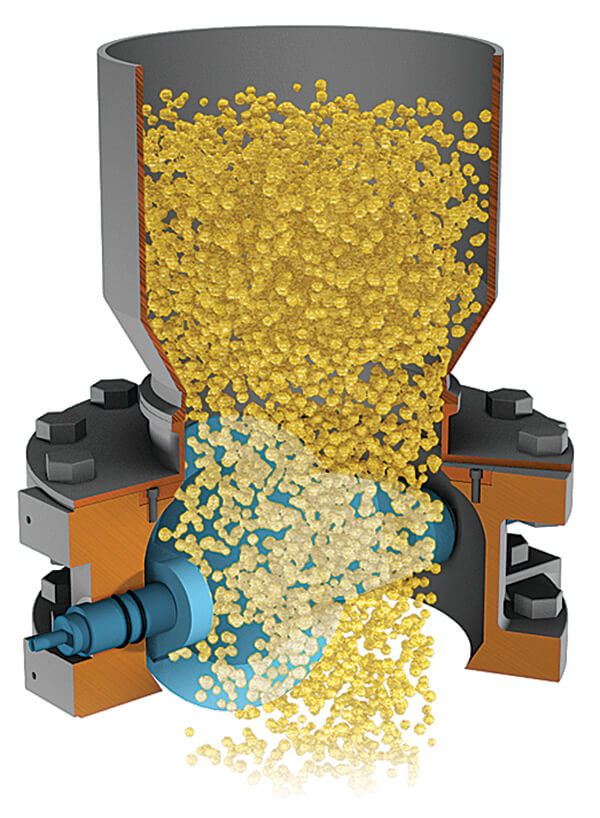

The Roto-Disc® valve has a unique design that slices through almost any sticky, gummy or abrasive substance without leaking, jamming-up or pinching product. The design eliminates hang-up points and the wiping action of the dome prevents material build-up. It is ideal for a wide-range of industries as an alternative to ball-valve, knifegate/slidegate valves and butterfly valves.

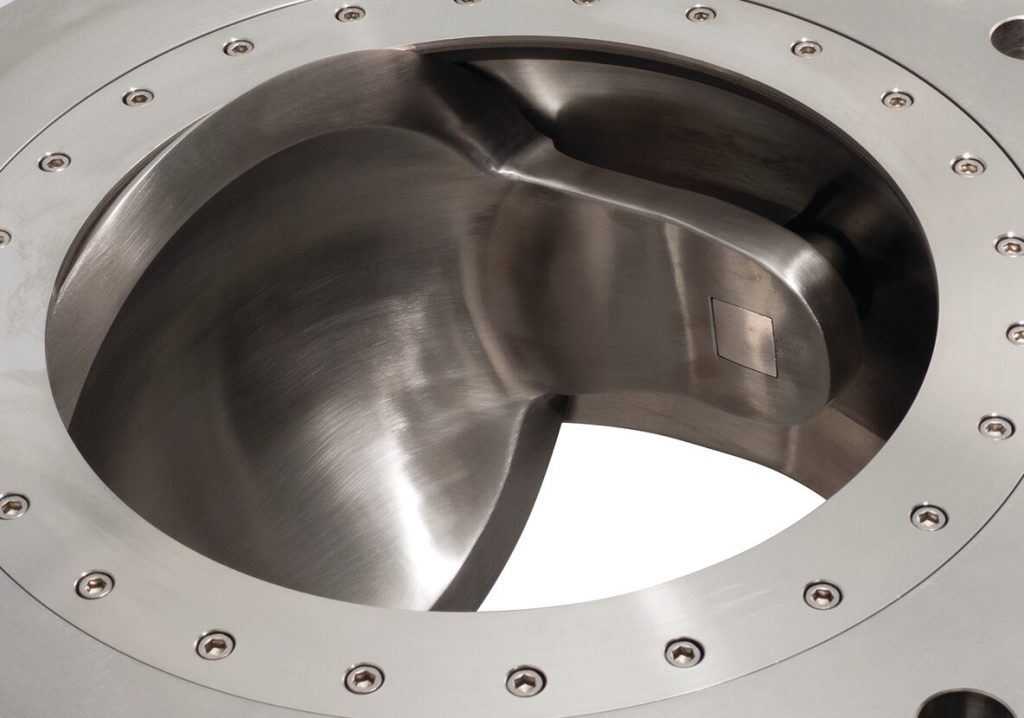

Direct-drive system eliminates taper/shear pins both inside and outside the valve. Square shaft ends and dome holes are machined to exacting tolerances and ground by hand to provide a perfect slip-fit that won’t allow the actuator and dome to become decoupled.

Seat replacement is a cinch – just take off the seat retainer and drop in a new seat. No shaft adjustment or alignment, no counter-rotating bushings – NO HASSLE!

Sticky, gummy, abrasive substances, powders, pellets, granules, chips – almost anything that runs through a process line can be handled by this valve.

If you can’t afford to spend time looking for replacements or have your valves out of service for repair, you need a Roto-Disc®. It could end your valve headaches forever!

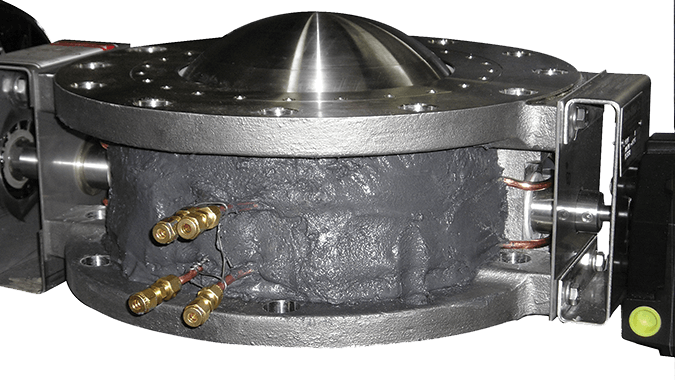

Material falls unobstructed through the inlet opening. Nothing is in the flow stream to cause product bridging, so you get the full flow capacity of the valve. Notice that the sealing surfaces are protected from direct contact with material.

As the valve begins to rotate closed, the dome wipes against the seat, cutting off the flow of product and pushing material above or below the valve instead of wedging it between the dome and seat. The design naturally resists abrasive wear and there are no pinch points or places for material to hang-up.

Closure is clean and the valve is fully seated. The dome and seat form a positive seal that eliminates leakage across the seat. Double O-rings prevent leakage through the stems.

Stainless Steel (304, 316, Duplex), Hastelloy-C, Inconel, Monel, Carbon Steel (4140, WCB, A36), Ductile Iron, Other alloys upon request

Reinforced PTFE (glass fiber, 316SS fiber, carbon fiber), PEEK, Ertalyte, UHMW, Other engineered plastics

Stainless Steel (304, 316, Duplex), AR400 Abrasion Resistant Steel, Hastelloy-C, Inconel, Monel, Other alloys upon request

Electroless Nickel, Stellite, Hard Chrome, Thin-Dense Chrome, Tungsten Carbide, Teflon®/PFA, Others

Full vacuum to 150psig below valve. Full vacuum to one bar above valve

-40°F – 1200°F (-40°C – 650°C).

*Pressure and temperature limits of an individual valve depend on a variety of application conditions and materials of construction of the valve.