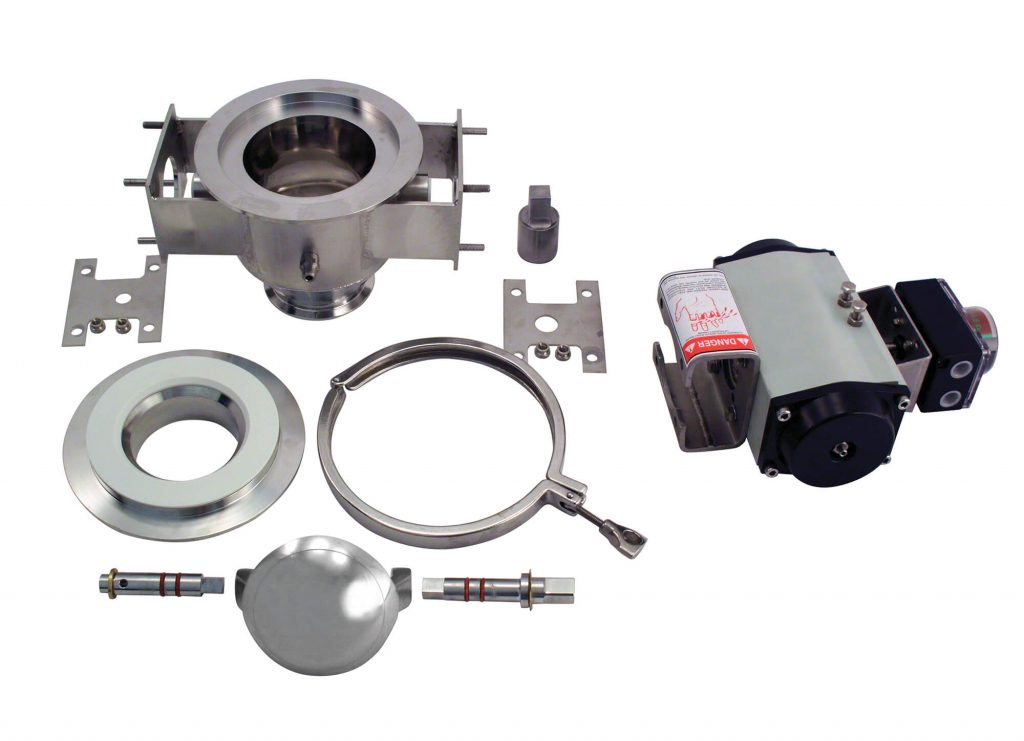

The Roto-Clean® valve incorporates the same essential features of the Roto-Disc® but comes in a light-weight, easy-to-clean design that can be disassembled and reassembled, by hand, in just minutes. Like the Roto-Disc®, the Roto-Clean® wipes itself clean with each cycle while slicing through sticky, gummy material build-up. All product contact surfaces are of FDA compliant materials. If you have to clean your processing equipment frequently and are tired of valves that gum-up, jam or leak, the Roto-Clean® may solve your problems forever – and cut downtime too!

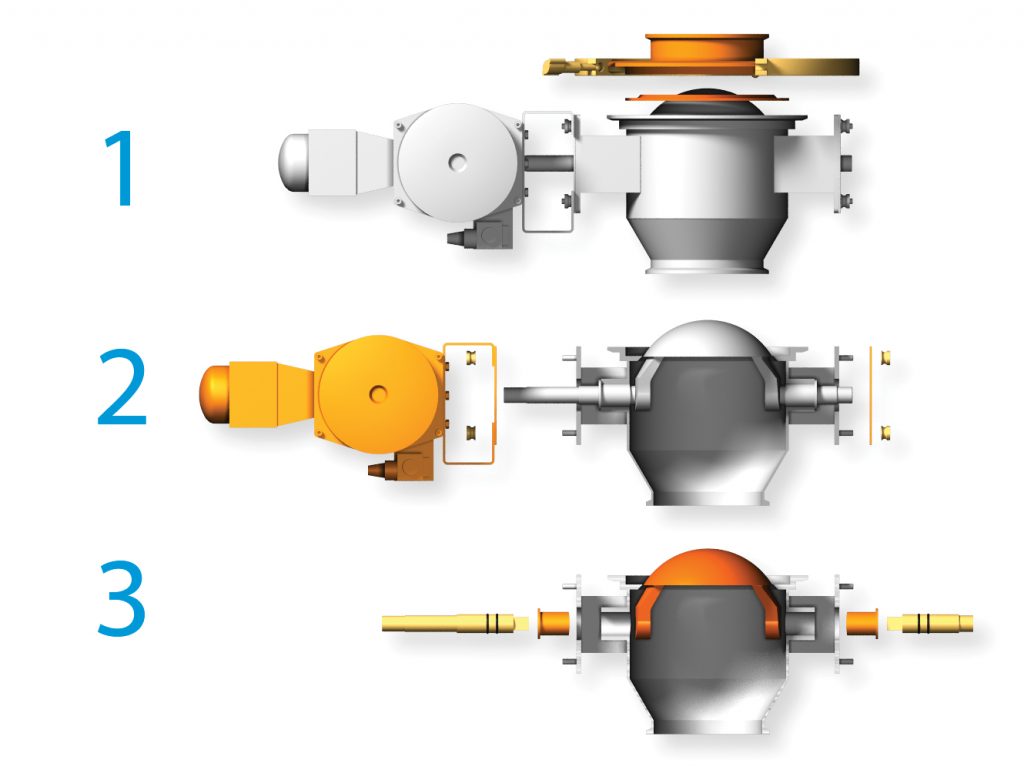

1. Remove Main Body Clamp and Inlet Plate

2. Unscrew Thumb Nuts and Remove Controls

3. Pull Out Shafts and Remove Dome and Bushings

Presto! No two product contact parts are still together and each can be cleaned and sanitized. Re-assembly is just as easy and in a few minutes, the valve is back in service. Clearances are undisturbed and the controls just slide back on.

Stainless Steel (304, 316, Duplex), Hastelloy-C, Other alloys upon request

Reinforced PTFE (glass fiber, 316SS fiber), PEEK, Ertalyte, Other engineered plastics

Stainless Steel (304, 316, Duplex), Hastelloy-C, Other alloys upon request

Thin-Dense Chrome, Teflon®/PFA, Others

Roto-Clean® valves are typically used in gravity flow or low-pressure/vacuum applications and at ambient to slightly elevated temperatures. Please consult Roto-Disc®, Inc. for Roto-Clean® applications at elevated temperatures or pressures.

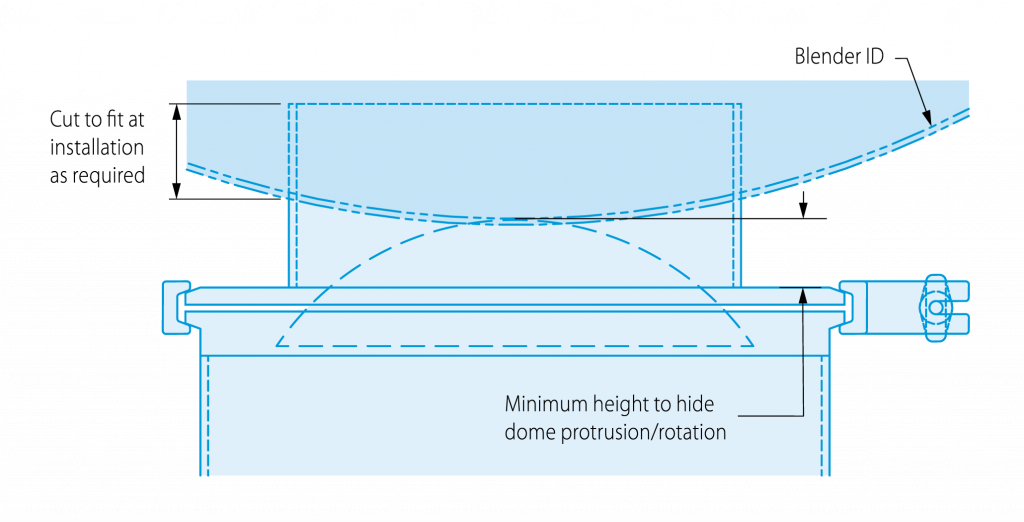

Extra stub length is provided for welding to blender bottom and minimizing dead space.