DRY MATERIAL MIXERS & BLENDERS NEED DRY MATERIAL VALVES

Roto-Disc®, Inc. shut-off valves are ideal for the inlets and discharges of atmospheric and vacuum mixers & dryers. The valves slice through material build-up and wipe themselves clean with each cycle. The sealing surfaces are not exposed to the flow of material and there are no hidden places inside for material to build-up. Unlike butterfly valves, there’s no vane in the middle of the flow-stream to restrict the flow, meaning smaller valves can be used without concern for bridging. Unlike slide-gate & knife-gate valves, the rotation of the dome pushes material above or below the seal rather than dragging across and wedging it into a recessed pocket which causes leakage and wear. And unlike ball valves, there is no un-sanitary dead-space for material to accumulate and jam the valve or cause wear as the ball rotates. These valves simply can’t handle the unique demands of solids handling applications!

Related Post: Roto-Disc, Inc., Announces Revolutionary Feeding & Measuring Capability

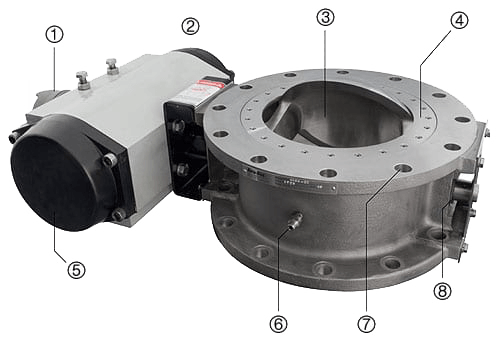

Roto-Disc valves eliminate all these design limitations because they are specifically designed for handling solids and slurries. They provide a positive seal against material leakage and differential gas pressure when used correctly. When installed on a blender outlet, the spherical dome takes-up dead space at the discharge port, thereby reducing unblended material. Food-grade & quick-clean configurations are available, as well as clean-in-place (CIP), hard-facing, hi-temp and many other construction options to meet the specific requirements of your application. For long, trouble-free service, Roto-Disc® valves are the ideal choice.

Contact Roto-Disc, Inc., or call 513-871-2600 for more information on what we can do for your company.